Ion microscopy with GaBiLi for FIB imaging, 3D analysis, and nanoscale tomography

Utilize GaBiLi - the FIB source containing Gallium, Bismuth and Lithium - for high-resolution ion microscopy

Ion microscopy enables high-resolution imaging to be performed on a given sample if the right ion species are applied. Although helium ion microscopy has been the choice for many sophisticated imaging applications, Gallium-Bismuth-Llithium provides advantages beyond pure FIB microscopy, with a single ion source emitting multiple ions at highest beam current stability. VELION FIB-SEM is equipped with a Liquid Metal Alloy Ion Source (LMAIS), which emits multiple ion species simultaneously from a single source with a subsequent ExB mass separation filter. This technology enables the individual characteristics of light or heavy ions to be utilized for ion microscopy.

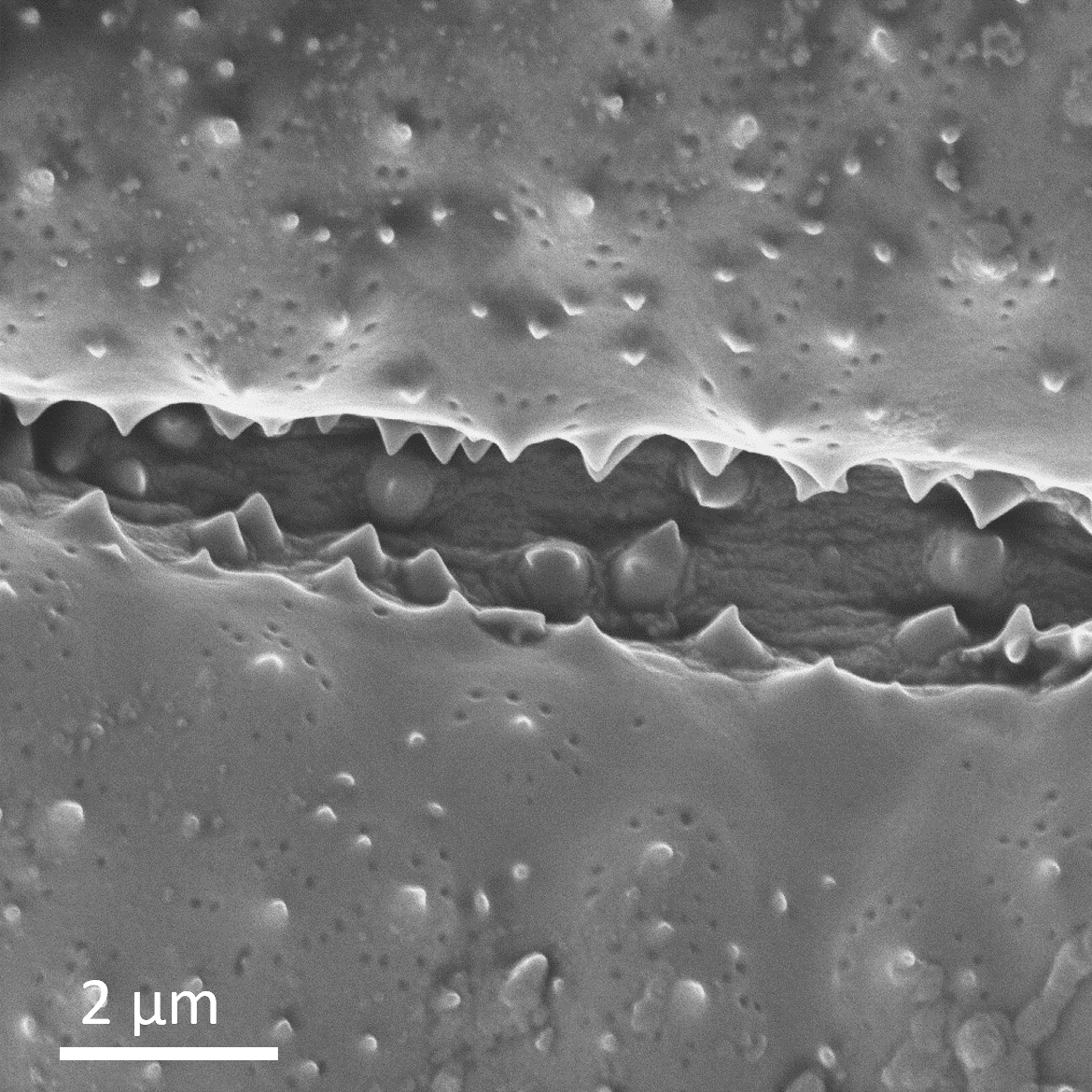

Bismuth ions and Lithium ions are applied alternately for 3D ion microscopy. Appropriate Bi beam milling strategies are effectively employed to ensure smooth and uniform delayering of the sample while milling the substrate. Intermittent scanning ion microscopy with lithium delivers high-resolution images between respective milling steps, which can then be combined for a 3D nano-reconstruction of the sample.

Surface sensitive focused ion beam microscopy with highest resolution

Equipped with a Multi Species Ion Source containing Gallium, Bismuth and Lithium (GaBiLi), VELION is a powerful ion microscope which allows 3D sample analysis for reconstruction at the nanoscale. Beside the heavy ions Gallium and Bismuth, GaBiLi contains Lithium as the lightest ion available for LMAIS, which is very suitable for FIB imaging. Lithium FIB enables ion microscopy to acquire high resolution 2D ion images. Lithium follows Helium in the periodic table and Lithium FIB has the lowest energy spread and virtual source diameter of all LMAIS ions resulting in excellent ion microscopy capabilities at highest lateral resolution

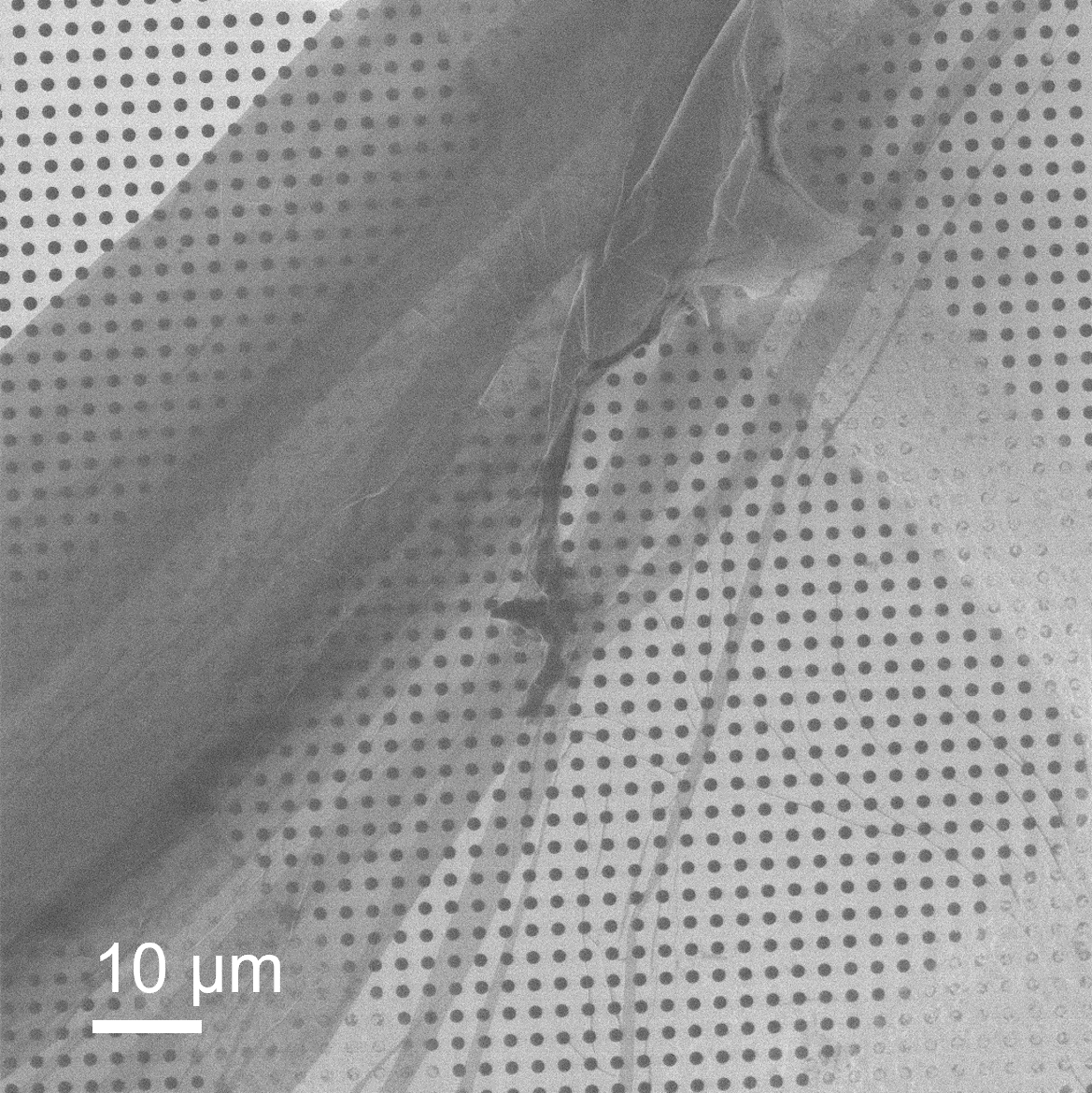

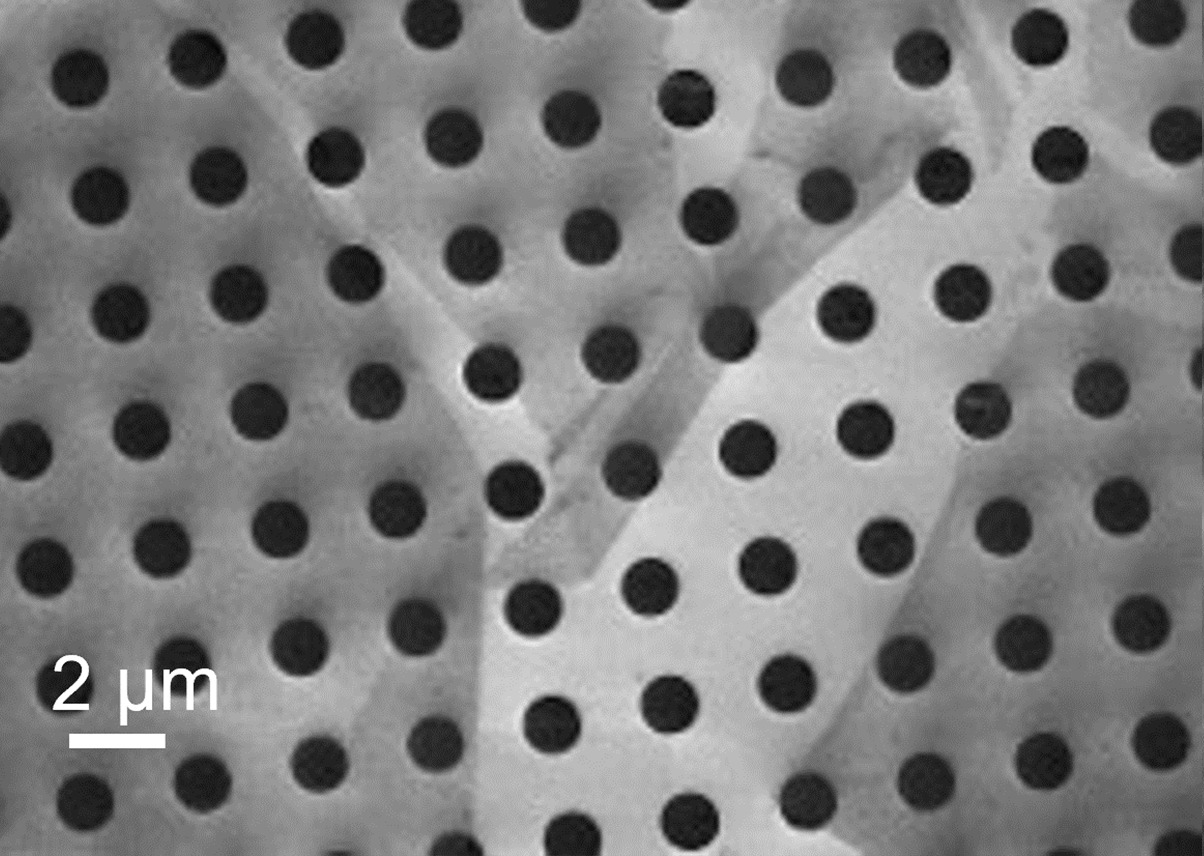

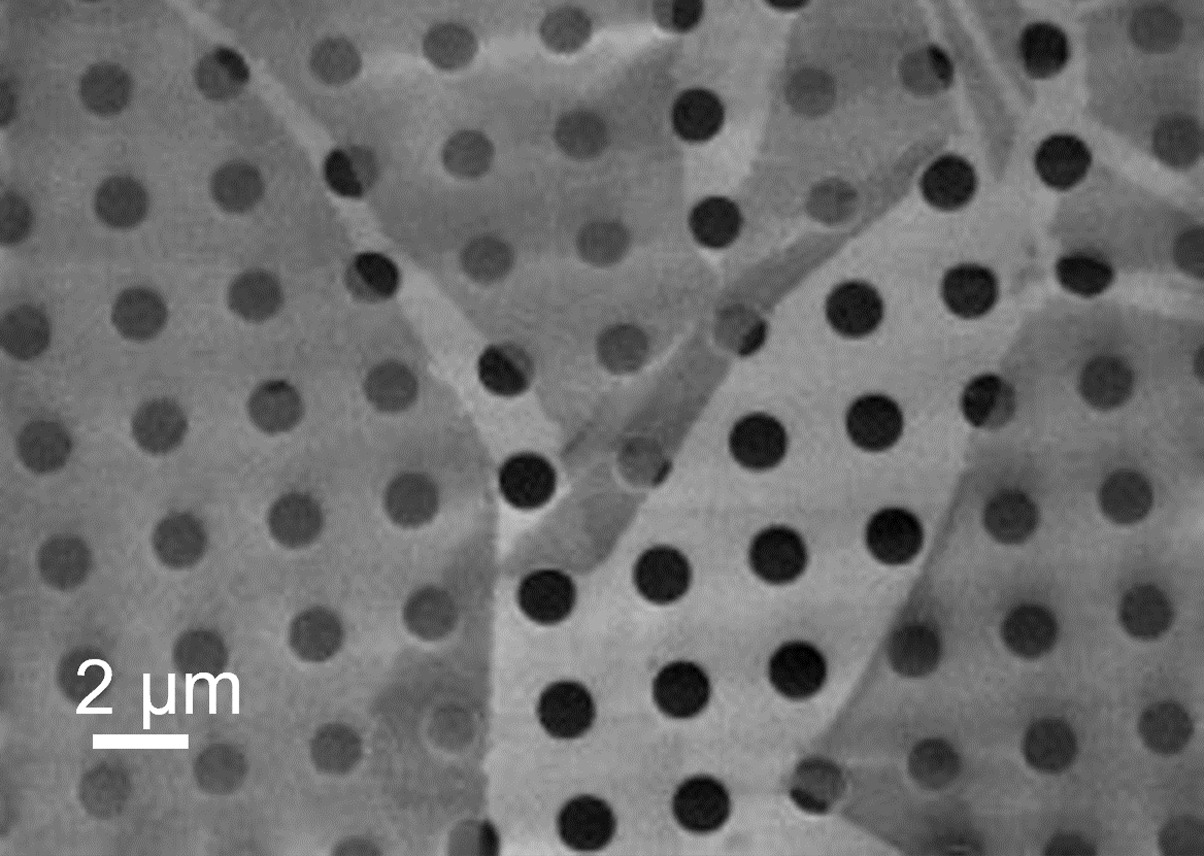

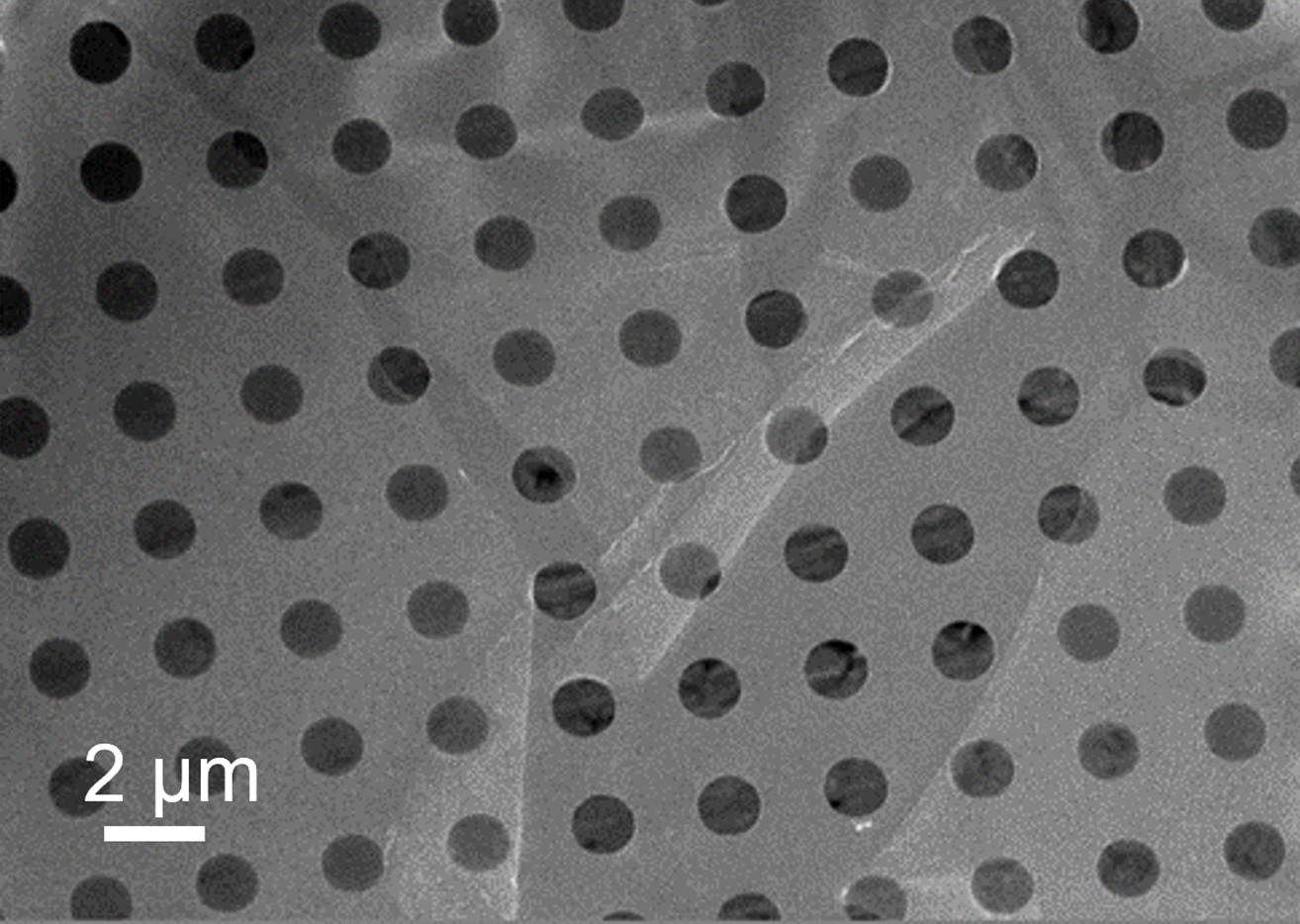

Comparison of ion images from GaBiLi ion source of a CNM with the corresponding SEM image (right).

Lithium ion image (left) and Bismuth Ion image (middle) of a single CNM on perforated carbon foil.

Both ion images resolve more details than the SEM Image and provide much higher image contrast between the different areas of the sample. Even the fold of the CNM in the center is clearly visible in both ion images. It is immediately visible that the Lithium ion beam delivers best results: The image appears contrasty, and the thin membrane remains well preserved. Because of the high surface sensitivity Lithium ion beam is well suited to image ultrathin CNM with a high signal to noise ratio.

Similar to a helium ion microscope, images acquired with a FIB microscope using lithium not only have a very high resolution, but also allow low-damage characterization of the sample.

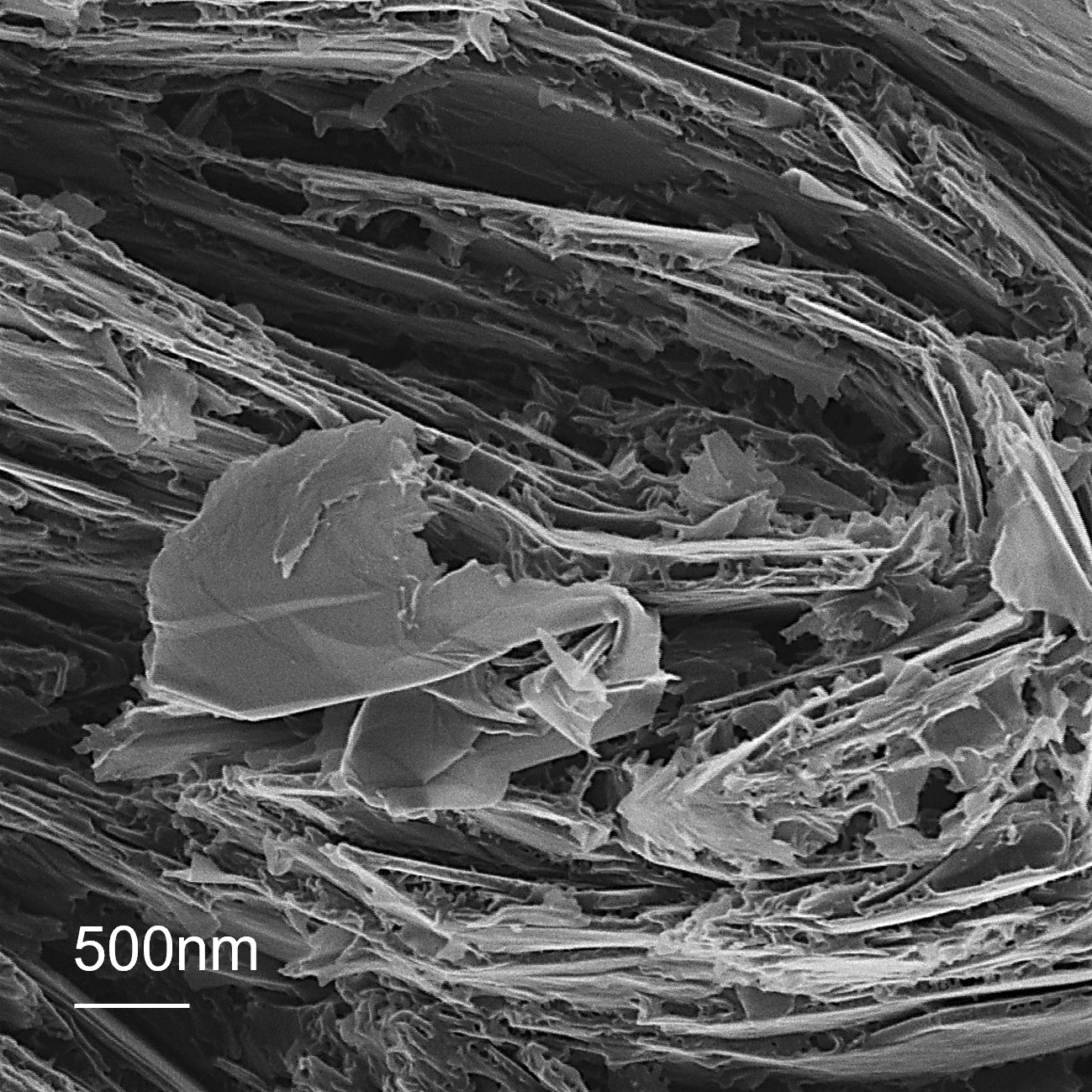

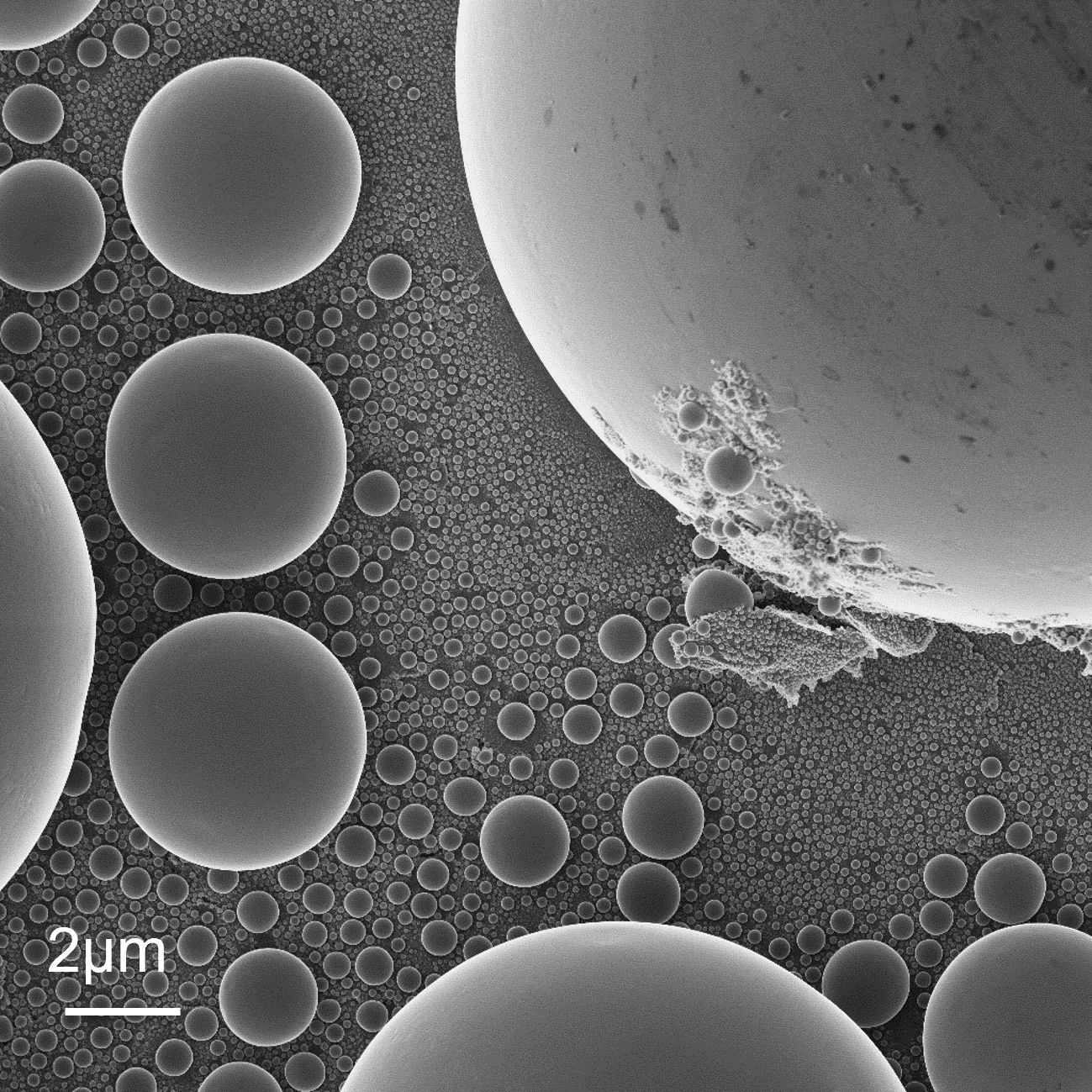

Lithium ion images of Bi2-Ca2-Co, graphite and Sn/C showing the high depth of focus, the high surface sensitivity and the high image resolution.

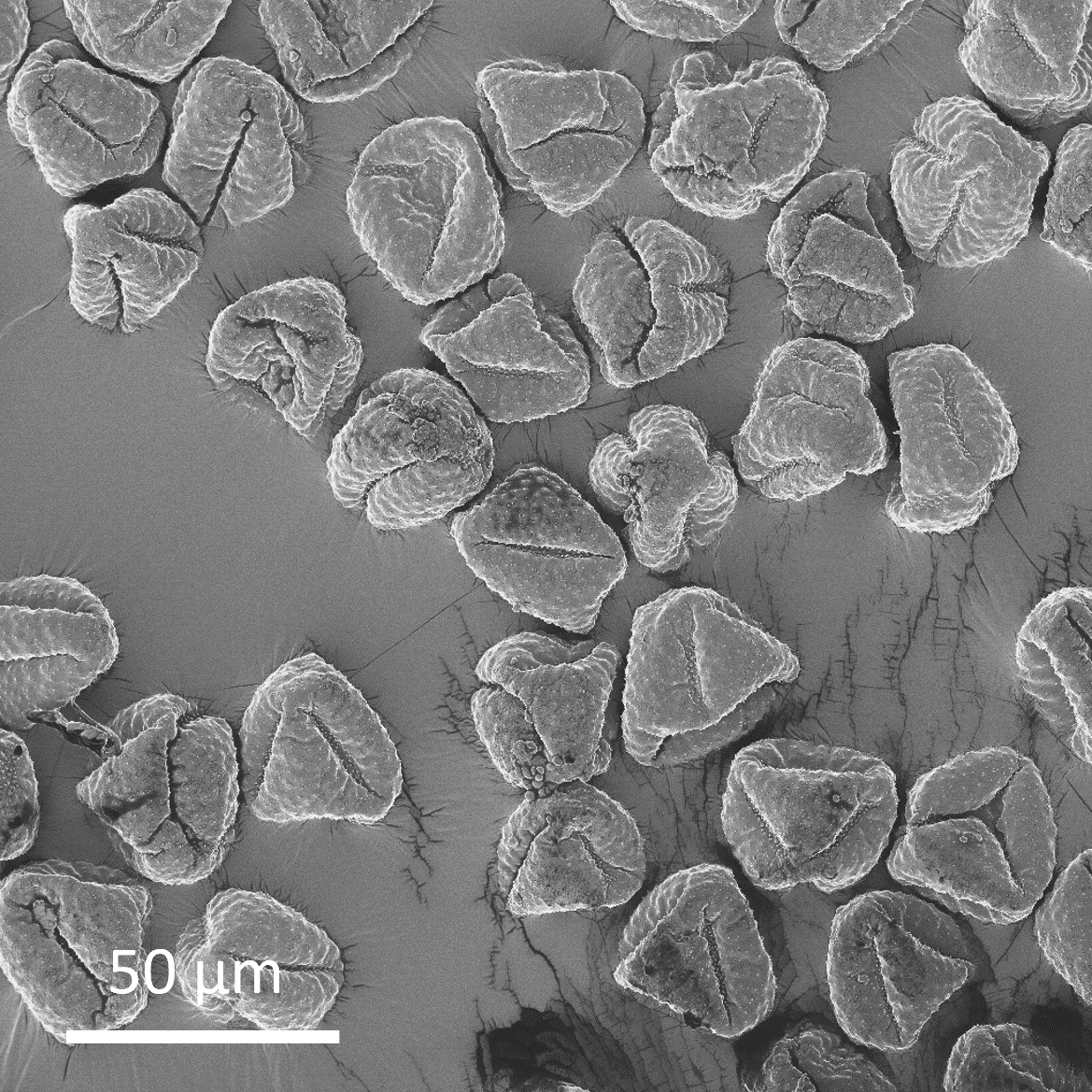

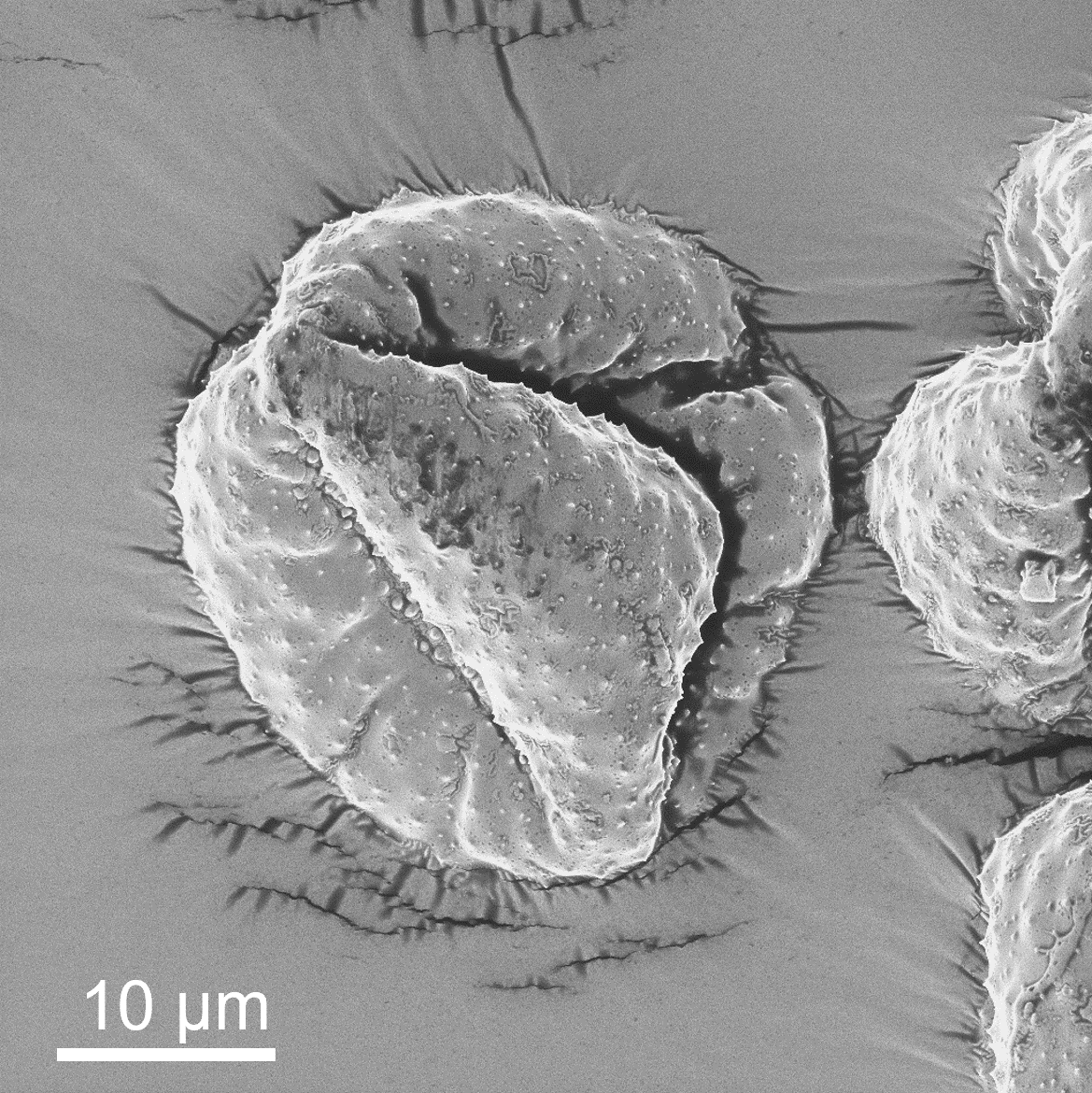

Dry pollen grains of Ranunculus repens, sample courtesy of Michael Laumann (University of Konstanz)

Combining an ion microscope with precise, easy, and efficient milling

The VELION FIB-SEM system enables FIB imaging to be performed with various ion species including Lithium. Due to its unique setup with a vertically mounted FIB column, the ion beam of either Lithium, Gallium, or Bismuth is always perpendicular to the sample surface. IONselect offers the ability to change ions reliable and quickly without sample tilt.

In this way, the sample can be milled and imaged at highest precision and accuracy. Bismuth, Gallium, and Lithium beams can be switched instantly and automatically, and are subsequently applied to the sample either for milling with heavy bismuth or gallium ions, or for light-ion microscopy with lithium. 3D nanoscale tomography becomes possible at unrivaled stability and fidelity.

After each step of uniform delayering, high-resolution, damage free 2D images with lithium are acquired. In a “flipbook”-style manner these images are stacked precisely on top of each other and are combined for a 3D nano-reconstruction of the sample.

Depth resolution and surface smoothness can be designed by choosing from gallium or bismuth ions or Bi cluster for milling. On top of that, the precision of the laser interferometer stage enables the imaging of each layer at the exact same position. That way a highly accurate stacking of the single images and therefore the creation of high-precision 3D models of the sample is possible

A workflow alternately using bismuth ions for fast sample delayering and lithium for imaging can be combined with the precision of a laser interferometer stage to result in a powerful ion microscope for 3D imaging.

Taking advantage of a lithography platform for ion microscopy

The VELION FIB-SEM system is based on Raith lithography equipment with a lithography platform matured over decades. In addition to the specific architecture and the advantages that derive from the use of a laser interferometer stage, VELION’s smart patterning strategies guarantee homogenous milling of the sample, regardless of the sample requirements.

For more information about the VELION FIB-SEM system with ion microscopy capabilities, visit the VELION product site. Should you have any further questions, please do not hesitate to get in touch.