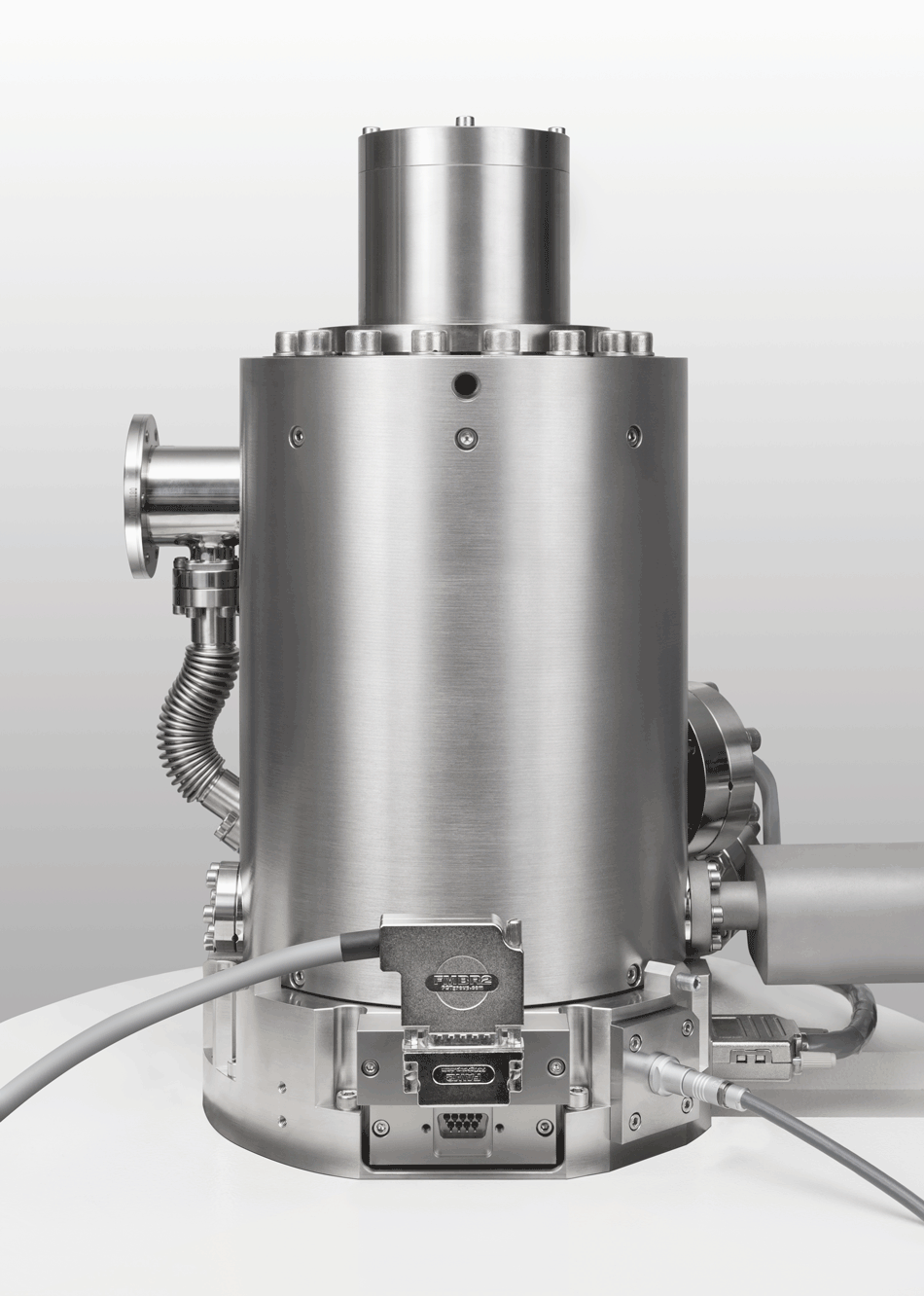

FIB column for advanced nanofabrication

When a focused ion beam (FIB) is employed, direct patterning techniques like

- milling,

- gas enhanced etching,

- gas assisted deposition,

- implantation, and

- functionalization

all become available. Raith’s proprietary source and column technology advances FIB to the performance level of a lithography tool and truly defines a new state of the art in FIB technology. Raith’s FIB column nanoFIB has been designed to be the primary technique in the dedicated lithography system VELION and meets all the critical requirements of advanced nanofabrication including long-term stability, placement accuracy, and high resolution.

Questions?

If you have any questions or need more information, just get in touch!

Long term stability

The nanoFIB column shows exceptional stability due to the liquid-flow optimized ion source and the patented emission control. The liquid metal ion source (LMIS) utilized in Raith’s FIB column differs from conventional LMIS in its geometry and the sophisticated manufacturing process of the metal base tip, which result in an inherently more stable ion source. Therefore, it provides long-term performance of guaranteed low drifts in probe current and beam position during continuous long-term operation.

Placement accuracy

The nanoFIB ion column uses dedicated low-distortion octupole deflectors enabling accurate beam deflection and pattern placement within a write field as well as stitching of multiple fields. The dedicated two-stage octupole deflectors are optimized for low aberrations and minimum distortion independently from the separate stigmation octupoles. As a result, deflection and stitching performance are unmatched and the nanoFIB deliveres the highest placement accuracy possible.

High resolution

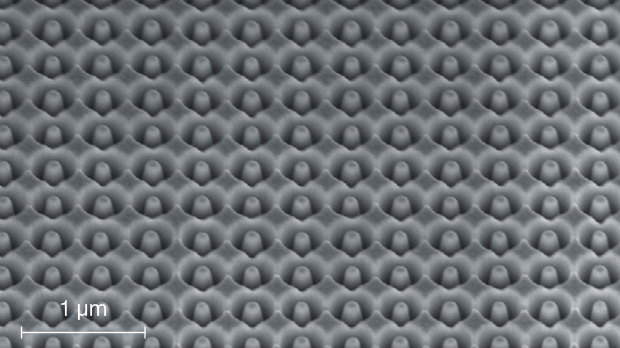

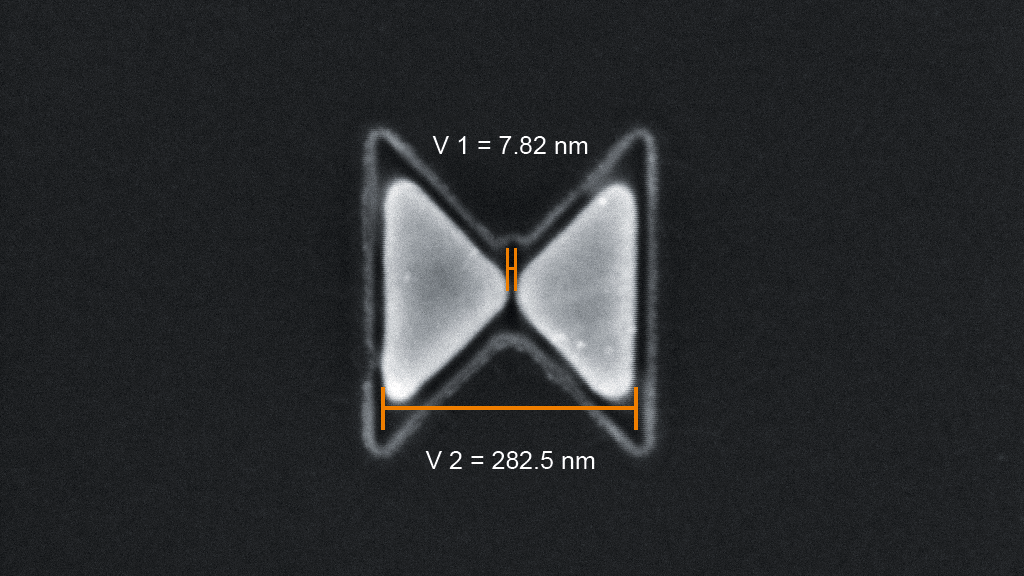

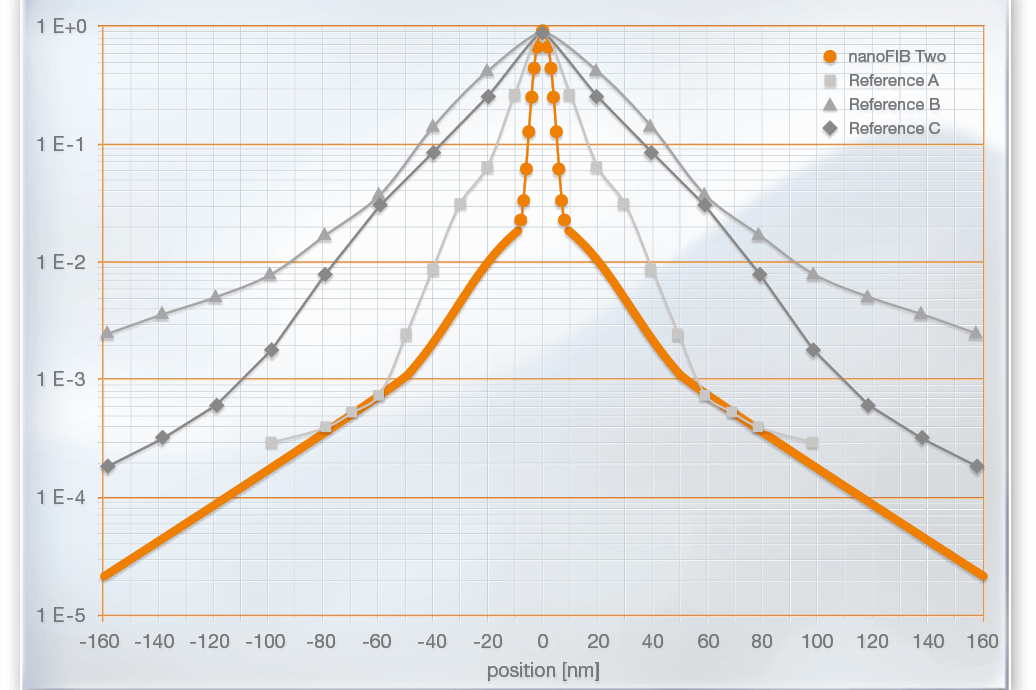

The design of the FIB column is optimized for highest resolution and excellent beam spot characteristics with a short optical length and working distance, as well as by focusing on the relevant beam current range for nanofabrication. A narrow central spot and record low beam tails enable high-resolution nanofabrication.

FIB column utilizes multiple ions from a single source

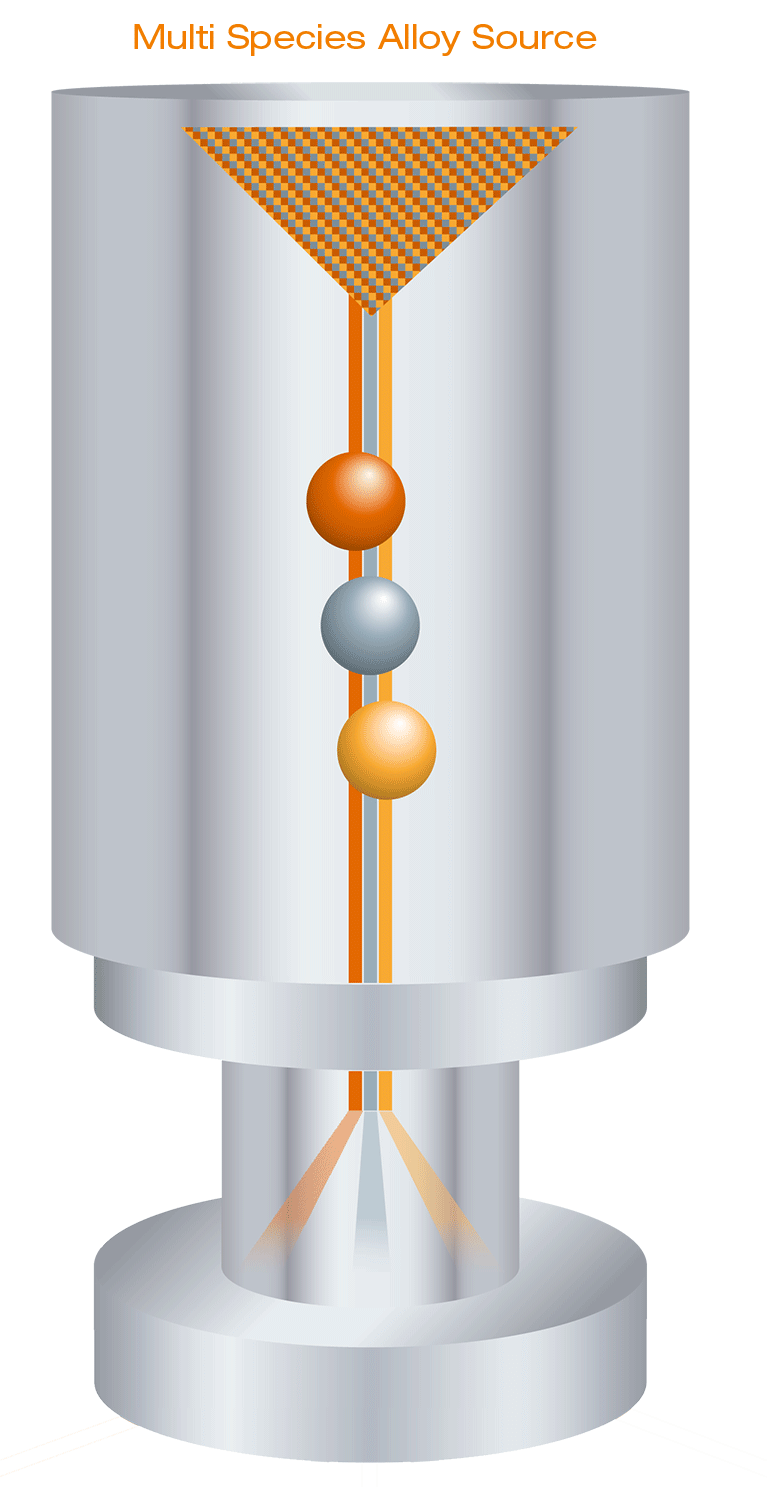

The IONselect technology enhances the nanoFIB column to employ new ion species beyond gallium.

A liquid-flow-optimized alloy ion source and mass separation filter (ExB Filter) enable easy switching between multiple ion species from a single source. The high resolution and stability of the FIB column is preserved while using e.g. Si or Au ion beams and handling is excellent. This multi-species ion beam technology allows enhanced nanofabrication and imaging at the sub-10 nm scale.

Benefits for applications

Stability and automation are crucial for reproducibility in nanofabrication. Furthermore, the excellent beam spot characteristic with record low beam tails allow smallest feature size for a large number of identical structures. This is extremly helpful for many plasmonic applications. When this stability, automation, and placement accuracy are coupled with the stitching capabilities of the VELION FIB-SEM system and the stitch-free exposure modes traxx and periodixx, the possibilities become even greater: larger area patterning over several mm, even for complex structures, without any stitching errors result in high perfoming devices. Learn more about traxx and periodixx, the stitch-free lithography exposure modes, here.

Get more Details

To get more details of the nanoFIB and the benefits for applications, download the white paper “nanoFIB for advanced focused ion beam nanofabrication.”