A decade of ion beam lithography: from entry-level ELPHY Multibeam to turnkey VELION Power User

When Kahraman Keskinbora started his Ph.D. in 2011 at the Max Planck Institute for Intelligent Systems in Stuttgart, one of his first tasks was to characterize a Fresnel Zone Plate (FZP) designed in Stuttgart and made by Raith’s Dr. Achim Nadzeyka using the IONline in Dortmund. During the synchrotron experiments, he used the FZP as an objective lens on a state-of-the-art scanning transmission X-ray microscope (STXM) called MAXYMUS at BESSY. The result was a huge success: “We were able to use the FZP up its 5th diffraction order, which showed how precise the zone placement was,” says Dr. Keskinbora. A couple of well-received publications [1,2] came out of this collaboration between Raith and MPI-IS.

“It was immediately clear to me and my advisors that IBL had a lot of untapped potential for the nanofabrication of diffractive X-ray optics such as FZPs and others” – Dr. Kahraman Keskinbora

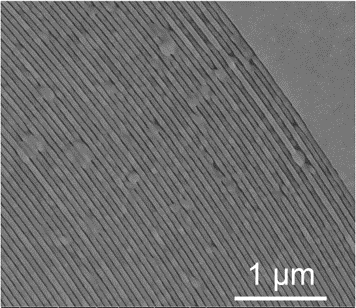

After the first round of promising results, recalls Dr. Keskinbora, he realized that the ELPHY Multibeam pattern generator system at MPI-IS, which was hooked up to their dual-beam instrument, could be used to develop new IBL routes to fabricate FZPs and other novel diffractive optics. “The ELPHY lithography attachment gave us the flexibility to design vectorial beam scanning strategies which were otherwise not accessible, and this had direct implications for the final quality of the optics,” explains Dr. Keskinbora. “First, I set out to make binary FZPs with improved resolutions in-house at MPI to be used at MAXYMUS, and have shown that we can use the ELPHY dual-beam system for rapid-prototyping of FZPs.”

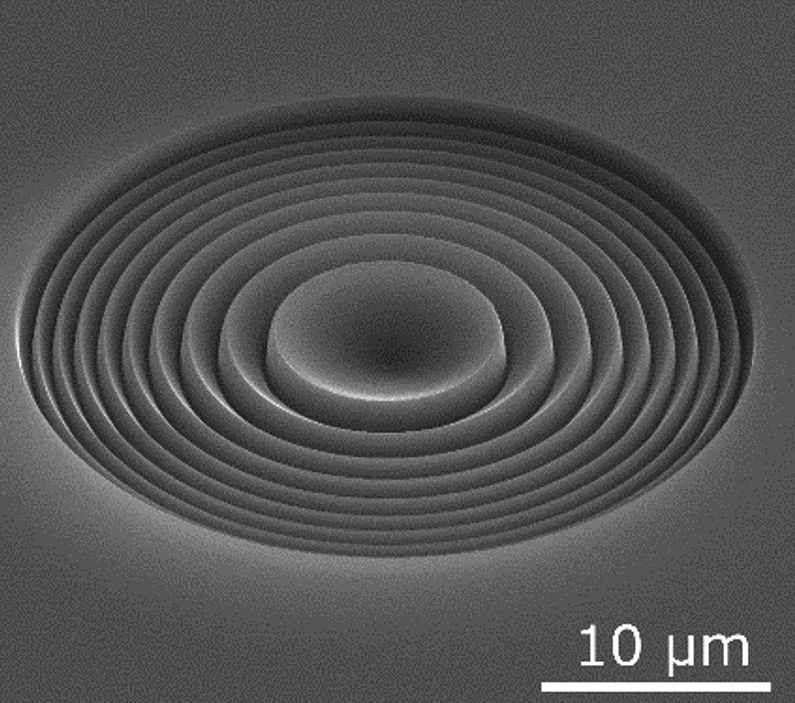

Soon after publishing those results in ACS Nano [3], Dr. Keskinbora turned his attention to the fabrication of 3D optics called kinoforms, which are X-ray counterparts of Fresnel lenses. “The challenge of making kinoforms pretty much boiled down to figuring out the right milling approach. Using bitmap files, which was a common approach to creating complex patterns with FIBs, was extremely restricting in both the quality and the size of the optic. So I wrote a MATLAB script that takes kinoform input parameters, creates the optical geometry, and generates an ASCII file with thousands of concentric circles with the proper dosage parameter. I could then easily feed this file to ELPHY, which allowed us to fabricate the first approximation-free X-ray kinoforms with parabolic surface profiles. I was extremely excited to have achieved this,” he explains. Those results made their way to the frontispiece of the journal of Advanced Optical Materials [4].

After becoming a group leader at MPI-IS, Dr. Keskinbora and his group members continued to use IBL to fabricate a variety of novel X-ray optics, from vortex generators and ion implantation lithography to making zone plates for use in coherent imaging experiments at MAXYMUS [5,6].

Towards the end of 2020, Dr. Keskinbora secured a research grant from the German Research Foundation (DFG) to continue his work in the USA. At that point, he crossed paths with Raith once again. “I met Torsten Richter at a photonics conference in Munich. He knew about the first zone plate collaboration between Raith and MPI-IS but didn’t know me personally, and I didn’t know him. When I introduced myself and told him that I would be going to the US, he told me all about the VELION” Torsten Richter introduced Dr. Keskinbora to our colleague at Raith America, restarting a fruitful collaboration. “I was very excited because I had never had the chance to work personally with IONline, and now I was going to have access to its successor,” Dr. Keskinbora explains.

“I was able to apply the lessons I learned from ELPHY Multibeam system on pattern generation and IBL to the VELION almost right away. Thanks to the close collaboration of Raith staff, I started producing results in no time.”

Kahraman Keskinbora explains, “VELION offers new possibilities including a multi-species ion source, high patterning resolution, and a very precise stage. Using the laser-interferometry stage, we can stitch pattern fragments accurately and write over vast areas. We can fabricate diffractive extreme-UV and soft X-ray optics with tiny nanoscopic features and diameters as large as one millimeter.” The first generation of those optics was tested at the Advanced Light Source (ALS) last year. New beamtimes are upcoming at FERMI, Elettra, Diamond, and ALS in the months ahead. Dr. Keskinbora’s final remarks are hopeful about the future of the technology: “With the multi-ion species source and precise delivery of dosage, the ion beam patterning and doping opened up new research avenues for us beyond X-ray optics. I see in every user meeting and conference that the IBL technology is finding broader applications in numerous fields, from quantum information science to 2D materials research, and that signals a very bright future for the science and technology of focused ion beams and ion beam lithography.”

Bibliography[1] Nadzeyka, A., L. Peto, S. Bauerdick, et al., Microelectron. Eng. 98 (2012)[2] Keskinbora, K., C. Grévent, M. Bechtel, et al., Opt. Express 10, 21 (2013)[3] Keskinbora, K., C. Grévent, U. Eigenthaler, et al., ACS Nano 11, 7 (2013)[4] Keskinbora, K., C. Grévent, M. Hirscher, et al., Adv. Opt. Mater. 6, 3 (2015)[5] Loetgering, L., M. Baluktsian, K. Keskinbora, et al., Science Advances 7, 6 (2020)[6] Levitan, A.L., K. Keskinbora, U.T. Sanli, et al., Optics Express 25, 28 (2020)