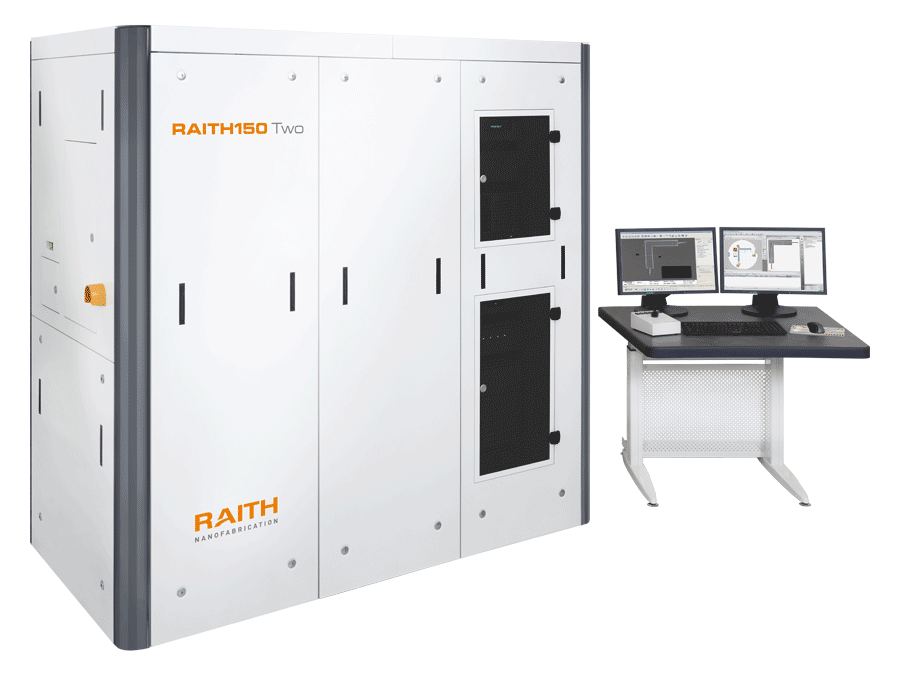

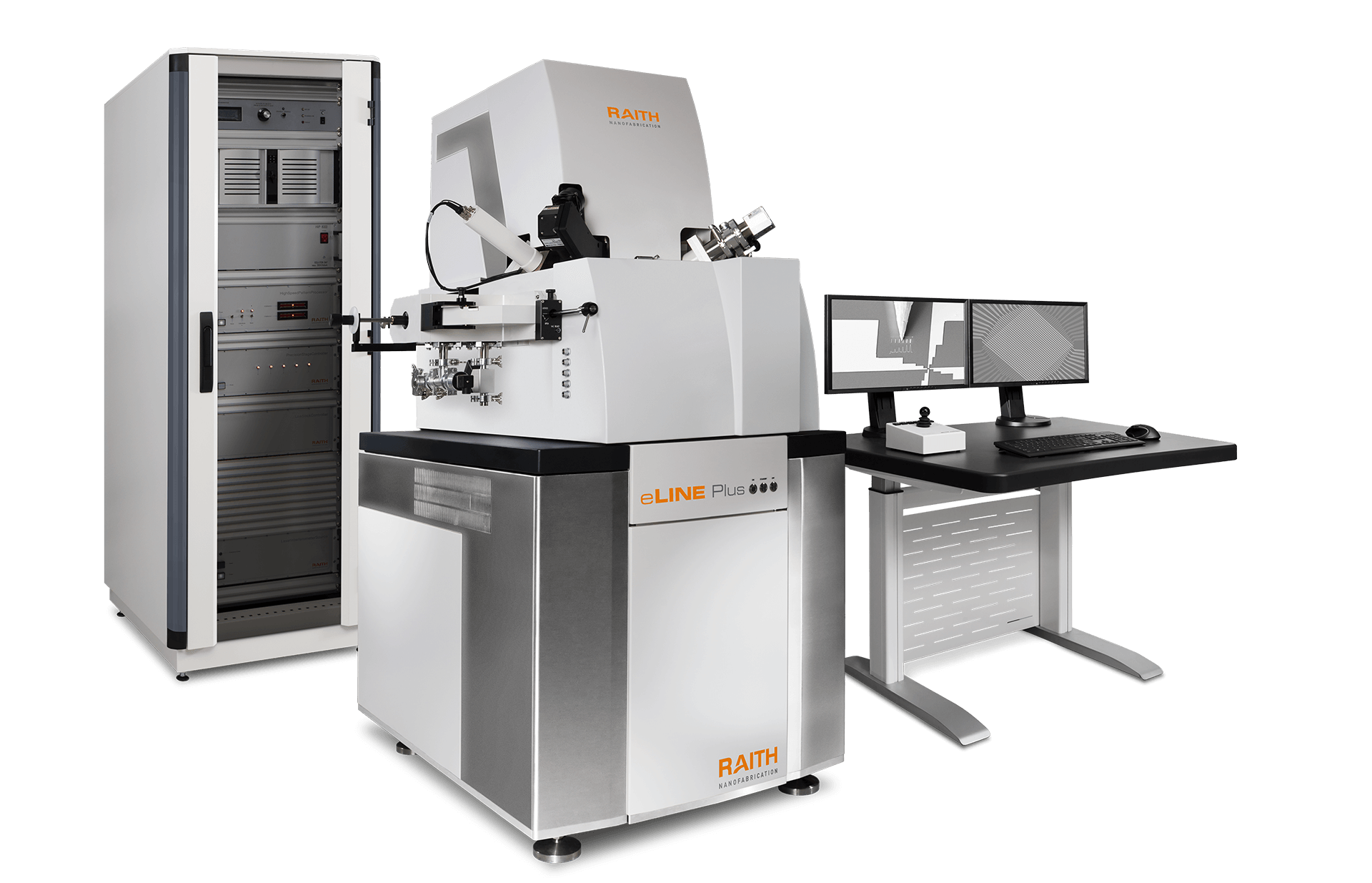

E-beam writer with ultra high resolution and thermal shield

The RAITH150 Two has established itself as a bestseller among universal high-resolution Electron Beam Lithography systems. It is utilized in research and nanotechnology centers worldwide and has proven its robustness in 24/7 use. The RAITH150 Two e-beam writer is designed to help with the transition from single-device-oriented research towards small-batch fabrication of nanodevices, thus bridging the gap between academic and industrial R&D with respect to its capilities in rapid prototyping of devices for industrial applications.

With features such as

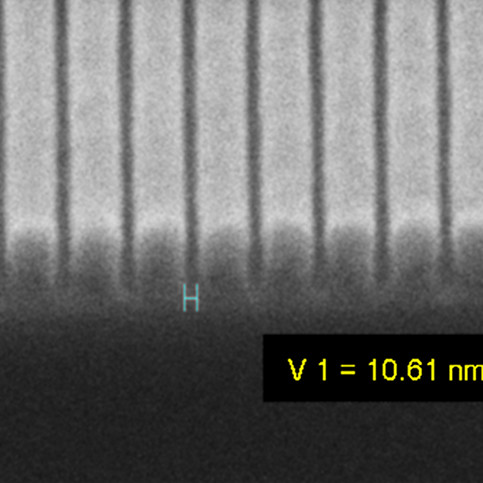

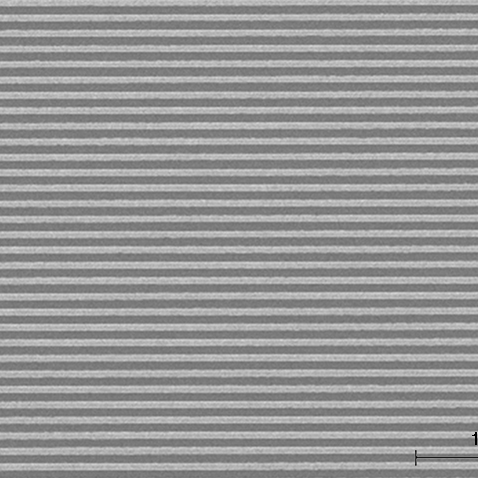

- ultra-high-resolution Electron Beam Lithography

- automated waferscale e-beam writing

- 30 kV Gemini column technology

- low kV exposure and imaging

- thermal shield, and

- unique split room setup,

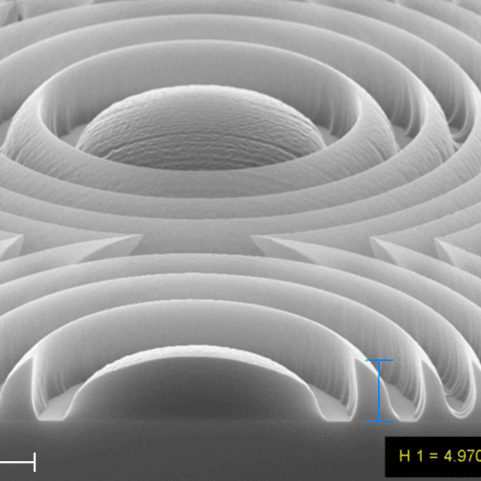

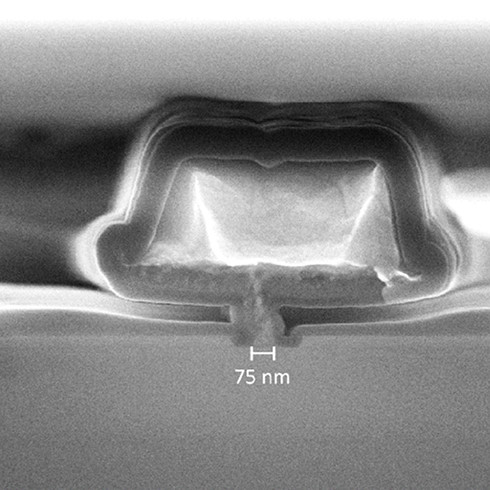

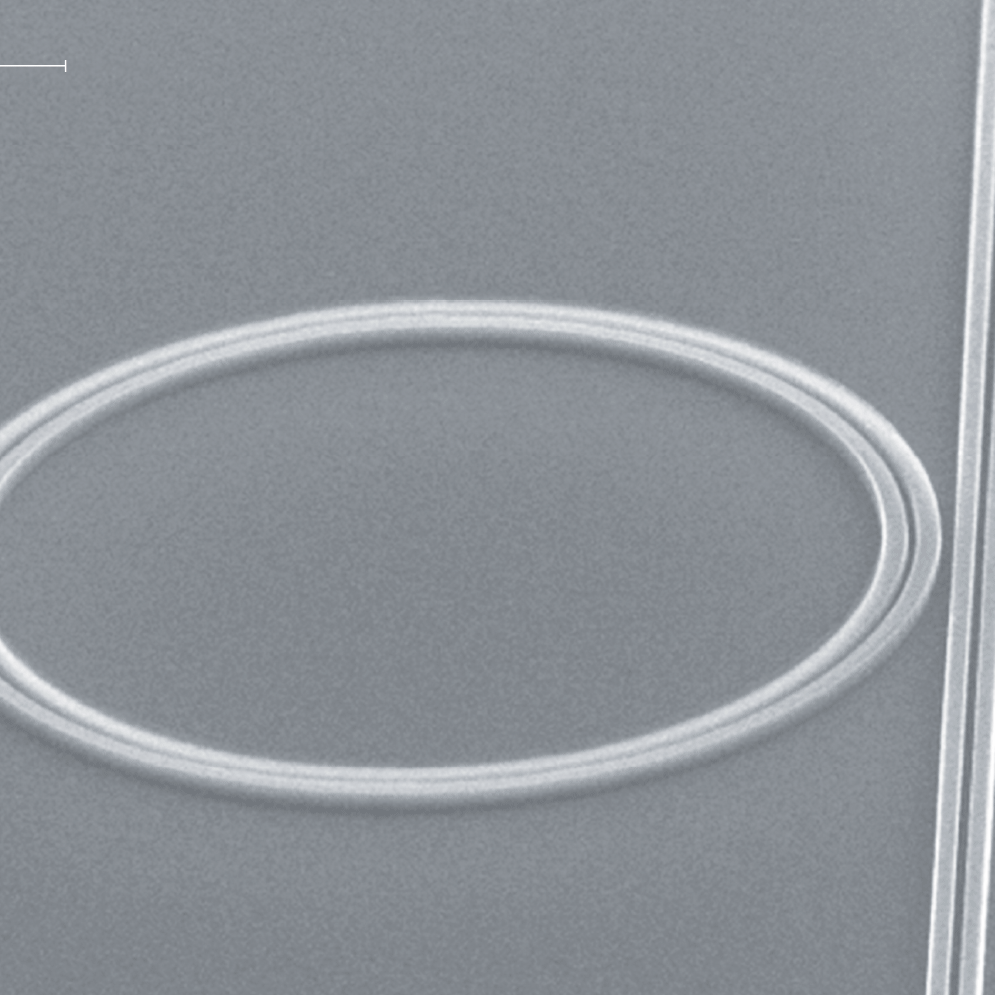

the RAITH150 Two can expose structures smaller than 5 nm and works with sample sizes from a few mm up to 8-inch wafers.

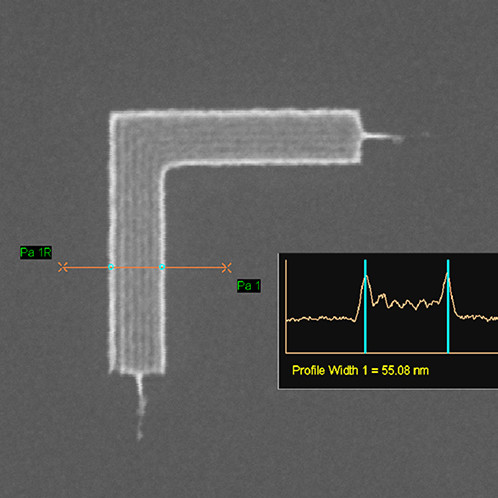

With its low kV imaging capabilties, the RAITH150 TWO e-beam writer also allows for surface-sensitive high-resolution inspection and process control. Exploiting all software functionalities for SEM imaging and dimensional metrology, the device optimization process can be efficiently shortened using the same tool as for device fabrication

As in most Raith systems, the intuitive nanofabrication software NANOSUITE is incorporated. This software ensures that even unexperienced users can immediately control the complete EBL process, yet also allows for advanced nanofabrication through an array of sophisticated features. Nanosuite features true multi-user management software so that all users find “their” system exactly as they left it – without “interference” from any other user! To find out more about NANOSUITE software, click here.

Features

Guaranteed line width

≤ 8 nm

Digital pattern generator

20 MHz

Sample handling up to

8’’

Precision and environmental tolerance

Like the VOYAGER electron beam lithography system, the RAITH150 Two comes with an environment-tolerant thermal shield which ensures system stability even in less ideal laboratory environments. Furthermore, the RAITH150 Two offers a unique split-room setup: the e-beam writer can be installed at a separating wall so that it stands in the grey room and can be operated from there, and is simply loaded/unloaded from the clean room area. This setup can save precious clean room space.

Hardware and software automation can take over easy and repeatable jobs for small batch production, spanning operation in single write fields, step & repeat, stitching, mix ‘n’ match mode, or a combination of all of them. A bright thermal field emission electron source in combination with various secondary and backscattered electron detectors delivers crisp SEM imaging, which ultimately results in unprecedented flexibility even when mark recognition is demanding and highest overlay accuracy is paramount.

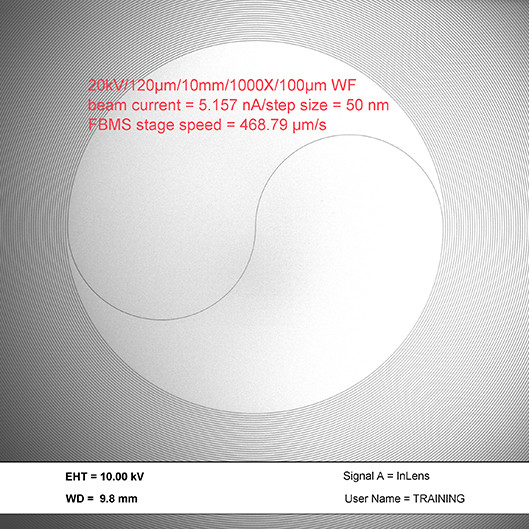

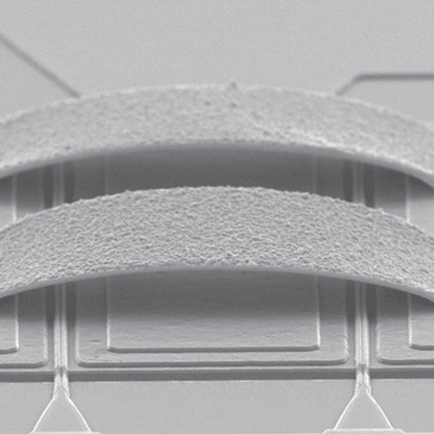

Stitching-error-free µ- or nanodevices are crucial for some of the latest applications of interest in the fields of optoelectronics for communication technologies or in micro- and nanoengineering. The RAITH150 Two e-beam writer can be optionally equipped with Raith´s unique traxx and periodixx functionality; these stitching-error-free writing modes use Raith´s proprietary fixed beam moving stage (FBMS) and modulated beam moving stage (MBMS) technology respectively.

Applications

Service

Specifications and system performance parameters are certainly drivers of decision-making where EBL systems are concerned. However, more factors need to be taken into consideration if efficient operation, continous uptime, and subsequent reliable support are to be ensured over the instrument system’s lifetime.

With a worldwide team of professional service engineers, Raith Service ensures you can make the best use of your system. When you decide on a Raith system, all site surveys together with environmental measurements, support with the resulting cleanroom laboratory setup, factory and on-site acceptances, and comprehensive on-site training are always included. Moreover, application support is available free of charge in all global time zones.

Raith service contracts follow a modular scheme and can be configured to match your individual requirements and budget. Visit our Service site or get in touch with us to learn more.

Download RAITH150 Two brochure

To find out more about the RAITH150 Two, the possible applications and specifications

the whole RAITH150 Two pdf package or the RAITH150 Two product brochure