Complex machines need easy-to-handle integrated control software

Software integration is the key asset of Raith products: No other system can match the Raith software suite in terms of flexibility, ease of use and safety – all embedded in a multi-user management system. All modules and accessories required for the entire array of workflows are fully integrated into a single software platform, with no visible third-party user interface. The Raith Nanosuite is the most comprehensive nanolithography software available and is the culmination of more than 100 person-years of software programming.

All you need to start manufacturing your first patterns is included in the standard scope of delivery for the entire Raith product portfolio:

- professional GDSII CAD layout editor,

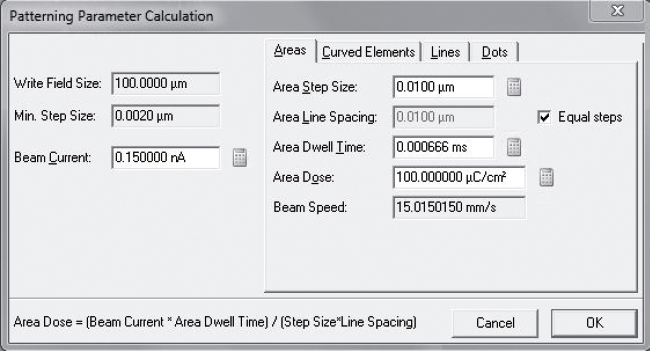

- exposure parameter determination,

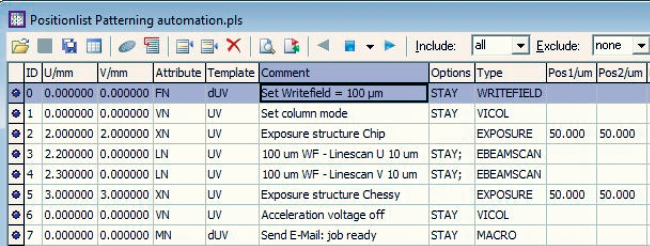

- task list for step and repeat exposures,

- automated or user-assisted mark registration for multilevel lithography,

- mix & match application, and

- tools for scripting in order to realize advanced and customized workflows and processes.

Proximity effect correction and CAD layout postprocessing can be exploited for challenging patterns, and if you need to generate 3-dimensional (grayscale) structures for e.g. integrated optics application, additional software is available to calculate the correct exposure dose distribution. Raith’s focus on software integration has ensured that instead of having to exchange data between different software programs, system operators can control all their system functionalities and exploit its capabilities from a single software platform.

Questions?

If you have any questions or need more information, just get in touch!

Key software modules for the entire nanofabrication workflow

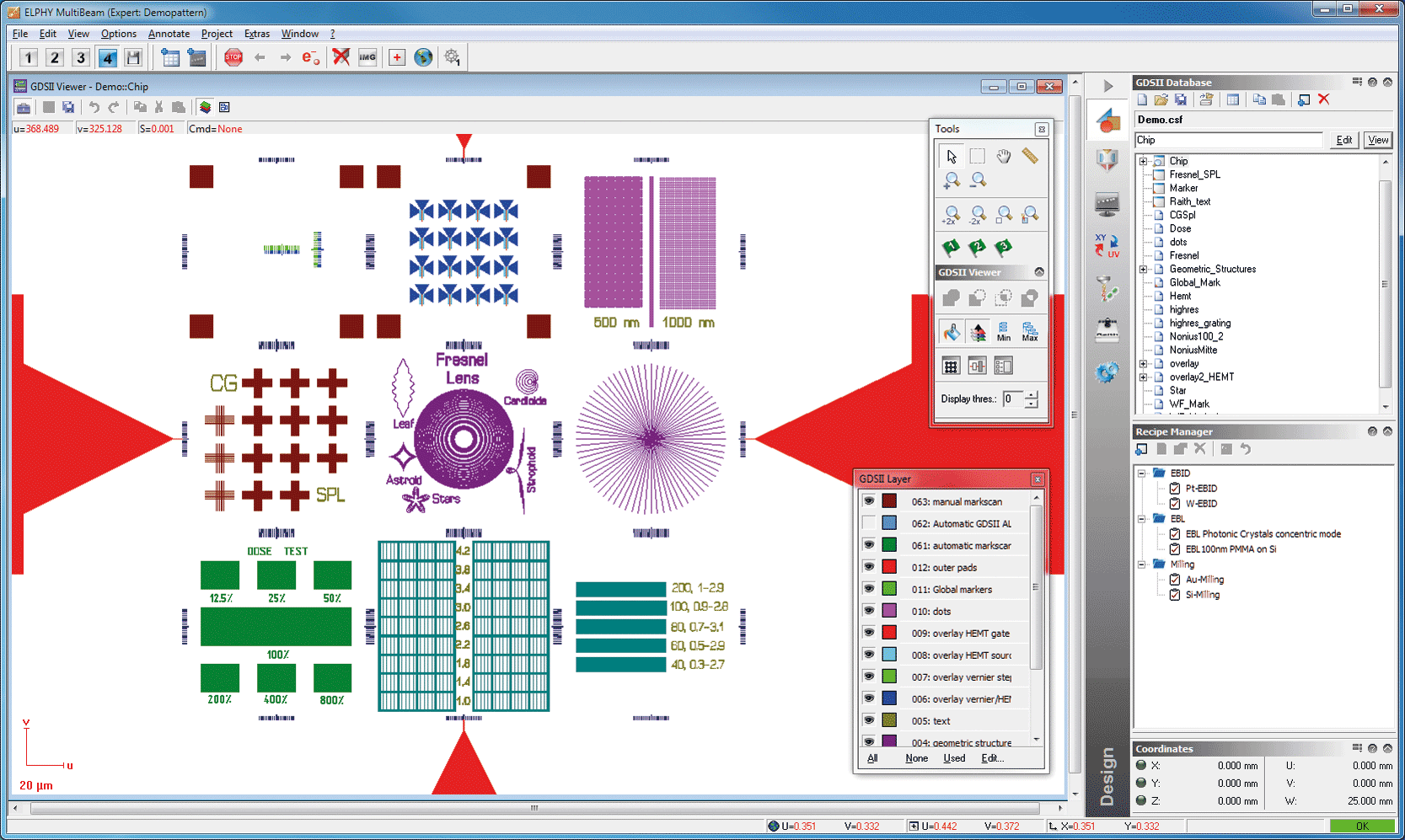

GDSII viewer / editor: A key advantage of having this fully integrated viewer and editor is the elimination of data conversion steps from external layout software. All changes of dimensions or, especially, patterning parameter doses are made directly in the design editor. Patterning processes can be started immediately without the need for further compilation. If preferred, standard formats like GDSII, DXF, CIF, and ASCII can be imported from AutoCAD, DesignCAD, or other GDSII layout software. Like all professional dedicated e-beam writers, ELPHY data management uses the industry standard of (hierarchical) GDSII.

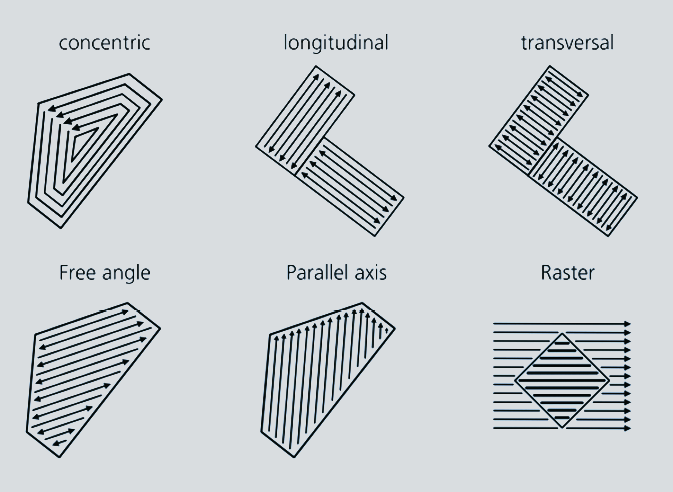

Patterning / Automation: In order to achieve optimum patterning results, writing strategies are kept very flexible. Full control over all exposure or milling parameters is given, including separate parameterization of individual shapes and activation of specific and individually applicable directional patterning modes. Automated step and repeat exposures are easily controlled by editing a position list (task list) or using drag-and-drop features. They can also be embedded in a complex, fully automated patterning process sequence containing not only the patterning jobs themselves, but also macros or scripts for column setup or exposure parameter changes, drift, beam current or focus correction, and even automated complex metrology or sample inspection tasks for process control. When finished, the system can even activate a column standby mode and deliver an immediate message to the system operator’s office PC to maximize efficiency of system usage with highest job yield.

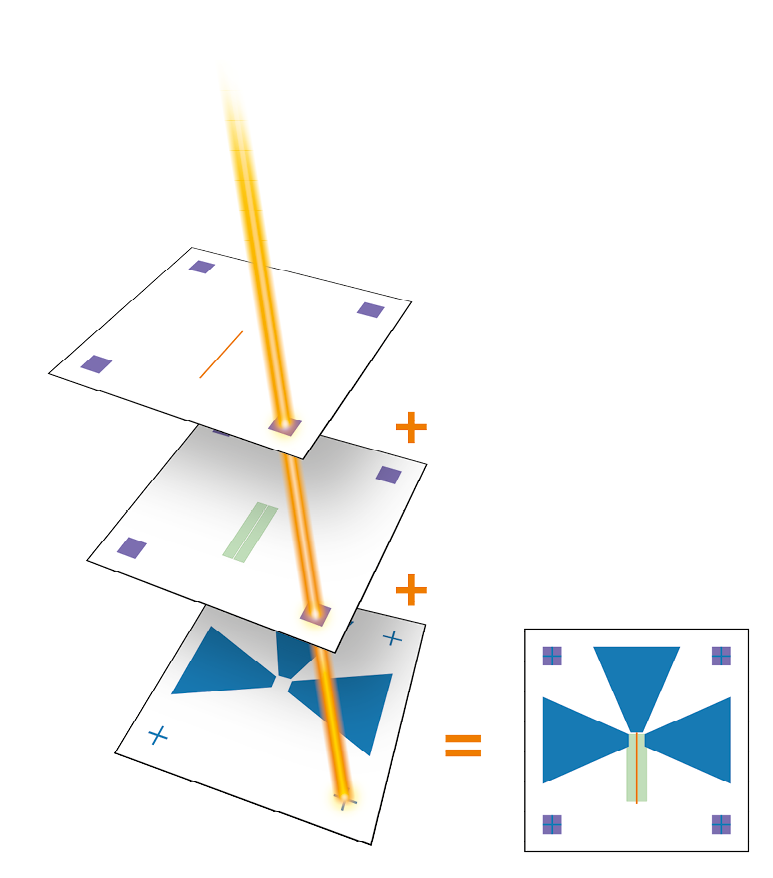

Multilevel lithography: Many lithography applications require alignment to existing structures or patterns. Raith systems offer software control over hardware alignment, meaning the writing field orientation is physically shifted, scaled, or rotated relative to the fixed sample such that additional features can be perfectly overlaid and implemented into existing ones. The user can assist during the mark registration procedure or apply fully automated mark registration sequences.

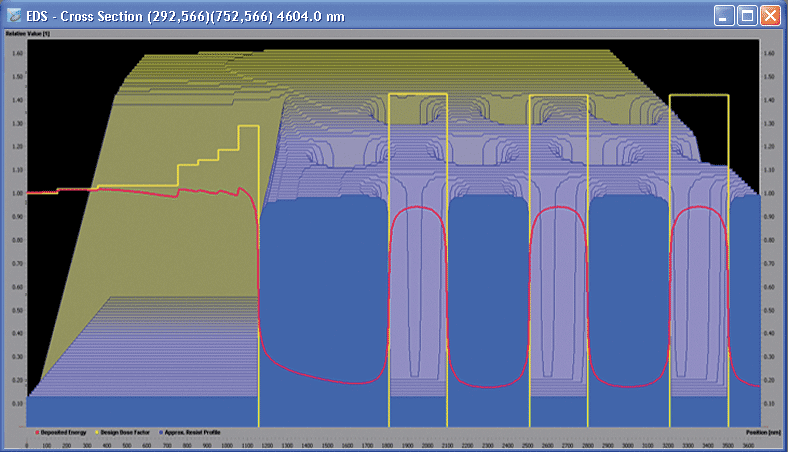

Proximity Effect Correction and 3D resist exposure simulation: Some applications require very accurate dose control in order to deliver optimum clearing doses, which can be crucial for fabricating dense nanostructures such as optical gratings or photonic crystals. The proximity effect correction package helps to optimize dose distribution for critical parts of your design. In order to identify, model, and optimize those critical parts prior to exposure, a 3D resist development simulation module is an integral part of the Raith Nanosuite.

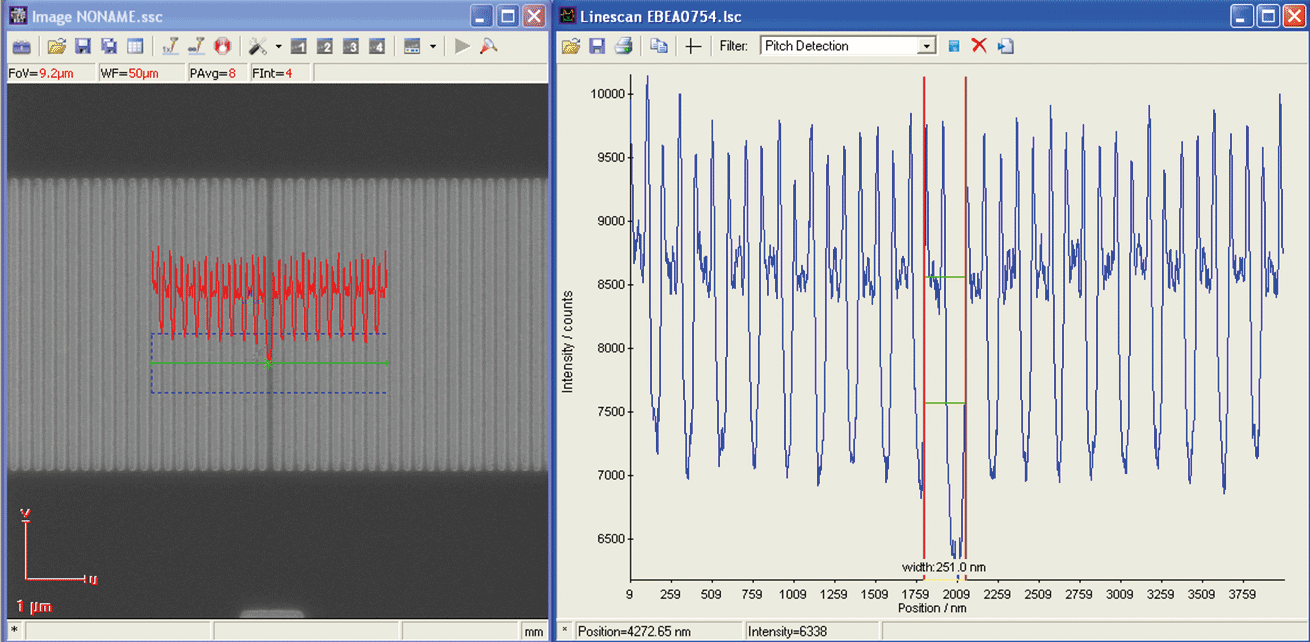

Metrology: Nanofabrication is one task, but efficient dimensionality check and respective subsequent process optimization quite a different one. However, they can all be accomplished using a powerful set of metrology algorithms and filters within the Raith Nanosuite, such as

- edge or distance detection,

- threshold,

- noise reduction, or

- cross correlation,

to name but a few – all automatable and exportable in e.g. histogram format for further analysis and evaluation

3D lithography: Increasing numbers of 3D (grayscale) applications are finding their way into areas such as optics or optoelectronics applications. Using the 3LITH software package, you can not only import grayscale bitmap patterns with associated contrast curves for 3D exposures, but can also design a set of diffractive optical elements, such as lenses, geometric 3D structures, (phase) holograms, and more.

Full software compatibility across entire Raith product portfolio

Whether you use an ELPHY attachment or a higher grade nanofabrication turnkey system, all software is based on the Raith Nanosuite. This means all your designs and processes will be compatible even when you use a different system within the Raith product portfolio, and there is no need to reiterate and reoptimize all your standard processes.