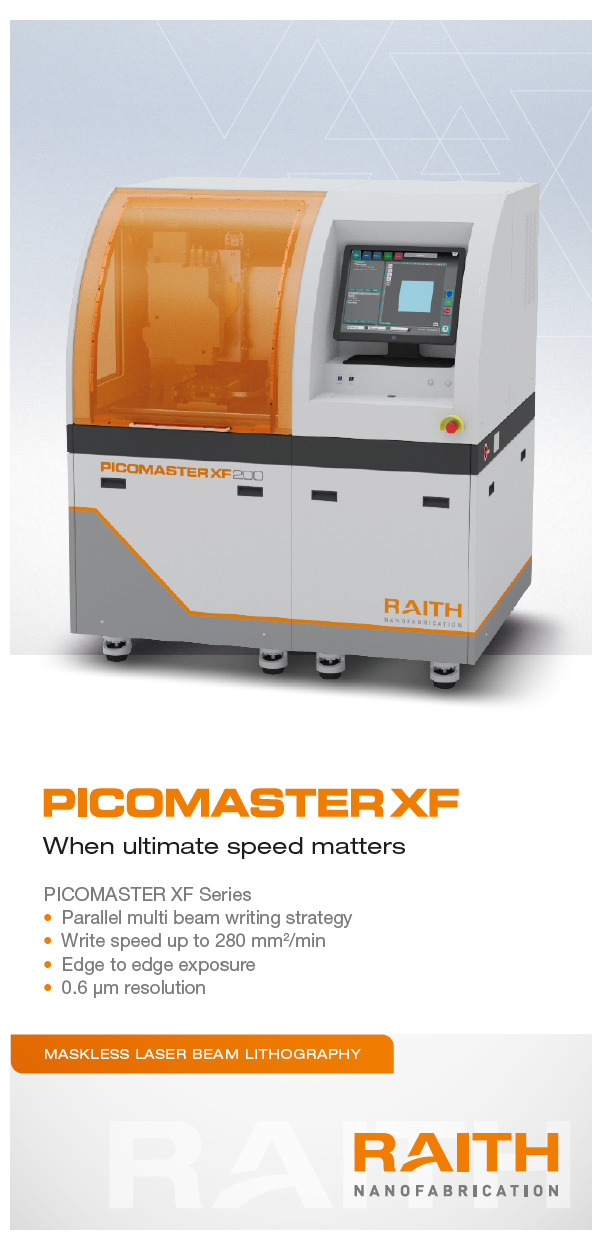

The maskless lithography system with ultimate speed

PICOMASTER XF is an eXtra Fast maskless lithography system that pushes the throughput of your microfabrication to the next level. With new multi-beam technology, PIOCMASTER XF operates at a writing speed of 280 mm²/min with an ultimate 600 nm resolution.

With features such as:

- Parallel multi beam writing strategy

- Down to 0.6 μm resolution

- Write speed up to 280 mm²/min at 0.6 μm resolution

- 256 levels of real-time grayscale lithography

- Proprietary autofocus even on challenging substrates

- Up to 8” x 8” exposable area

- Stitch-free exposure

PICOMASTER XF offers maximum throughput at high precision. With its high accuracy and speed, the PICOMASTER XF maskless lithography system is suitable for research labs and universities as well as for production nodes for semiconductors, electronics, photonics, mask-making, 3D lithography, diffractive optical elements, microfluidics, RF devices, LED, flat panels, and AR/VR devices.

PICOMASTER XF is a FASTER tool for your lab:

FLEXIBILITY: Can be flexibly configured to meet the requirements of even the most challenging applications by adding autoloading system, large-scale substrate writing capabilities (up to meters), full-process integrated workbench

ACCURACY: Offering high-accuracy laser power control to ensure precise doses, autofocus accuracy even on challenging samples and close to sample edges, and alignment accuracy down to 0.25 µm

SPEED: Offering multibeam exposure technology, the maskless lithography system PICOMASTER XF is over 100 times faster than single beam machines, achieving exposure of a full 6” wafer in 1 hour

THROUGHPUT: The PICOMASTER XF’s multibeam exposure technology, fast and precise stage mechanics, and software buffering system ensure stable high throughput

EASE of USE: Easy sample handling supported by inhouse-designed aligning tools and a powerful user interface for convenience in working with most common file formats

REDUCED MAINTENANCE COST: Smooth, quick, and cost-efficient maintenance with maintenance-free motion platform and long-lifetime optical module (10,000 hours), which is easy to replace with no need for a service visit

Features

Write speed up to

280 mm²/min

Resolution

0.6 µm

Grayscale levels in one go

256

Micro scale features for big substrates

PICOMASTER XF platform can support very big substrate sizes covering most demanding and emerging applications such as holography, big flat panels, and AR/VR devices. With autoloader and precision mechanics, PICOMASTER XF maskless lithography system is capable of delivering unique precision and ultimate 0.6 µm resolution over 1×1-meter substrates with a high throughput rate.

Applications

Raith Service - with you all the way

Where maskless lithography systems are concerned, a system’s unique capabilities and performance quality are certainly among the main drivers for decision-making. However, there are further factors to be taken into account, including efficient operation, continuous uptime, and subsequent reliable support over the whole system’s lifetime, which are always appreciated by our customers.

With a worldwide team of professional service engineers, Raith Service ensures that you can make the best use of your system. When you decide on a Raith system, support with the process setup, factory and on-site acceptances, and comprehensive on-site trainings are always provided with the systems. Moreover, complementary application support is available in different time zones.

Raith service contracts follow a modular scheme and can be configured to match your individual requirements and budget. Visit our Service site or get in touch with us to learn more.

Download the PICOMASTER XF product flyer

To find out more about the PICOMASTER XF, the possible applications and specifications download th PICOMASTER XF product flyer