High resolution FIB nanofabrication beyond gallium

FIB nanofabrication permits applications that are not possible with EBL or makes the process easier and faster in the case of other applications. Conventional FIB systems rely on gallium as the ion of choice. However, changing the ions to other elements yields even more advantages, including:

- prevention of contamination,

- functionalization,

- higher resolution, and

- increased milling rate.

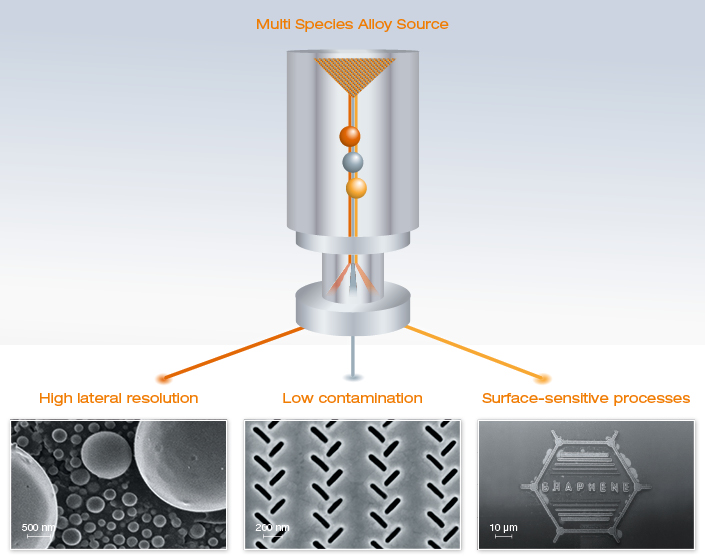

Raith’s unique IONselect technology enables easy switching between multiple ions from a single source, while maintaining the high resolution of the nanoFIB ion column.

Questions?

If you have any questions or need more information, just get in touch!

IONselect technology

Raith’s proprietary FIB technology has evolved to enable advanced nanofabrication and truly defines a new state of the art in FIB. The nanoFIB can even be extended for stable delivery of gold, silicon, or other ions with nanometer beam diameters. This unique IONselect upgrade path comes with a multi-species ion source and low-aberration ion selection optics.

This liquid metal alloy ion source (LMAIS) replaces the Ga LMIS and is based on a special flow-optimized tip geometry for the eutectic alloy material, ensuring long-term stability and improved lifetime. With automated ramp-up and emission control, it can be run as a source for standard FIB operation and used as a novel tool for nanofabrication. Since the alloy ion source provides simultaneous emission of various ions, easy switching between multiple species from a single source becomes possible without forfeiting the high resolution of the nanoFIB.

Offering a range of species

IONselect offers a range of species from doubly charged light ions to heavy ions or clusters, all with excellent handling. The ion species define the nature of the interaction mechanism with the sample and thus have significant consequences on the resulting nanostructures.

While light ions allow patterning of laterally smaller features and imaging with less damage, heavy ions offer faster milling rates or selective functionalization with better control in depth. This opens the door for unique yet-to-be explored nanofabrication techniques with low contamination, higher resolution or increased surface sensitivity.

Examples are use of a silicon ion beam for patterning thin layers with less contamination and higher resolution, or employing gold ions or clusters for specific functionalization. This technology is being applied in an increasing number of challenges in nanofabrication and imaging, and will pave the way for new breakthroughs in next-generation research.

To get more details on IONselect and nanoFIB and the benefits for applications, download the white paper “Advanced focused ion beam nanofabrication capabilities”.