George Washington University selects Raith electron beam lithography and large area SEM imaging solutions to take their research to the next level

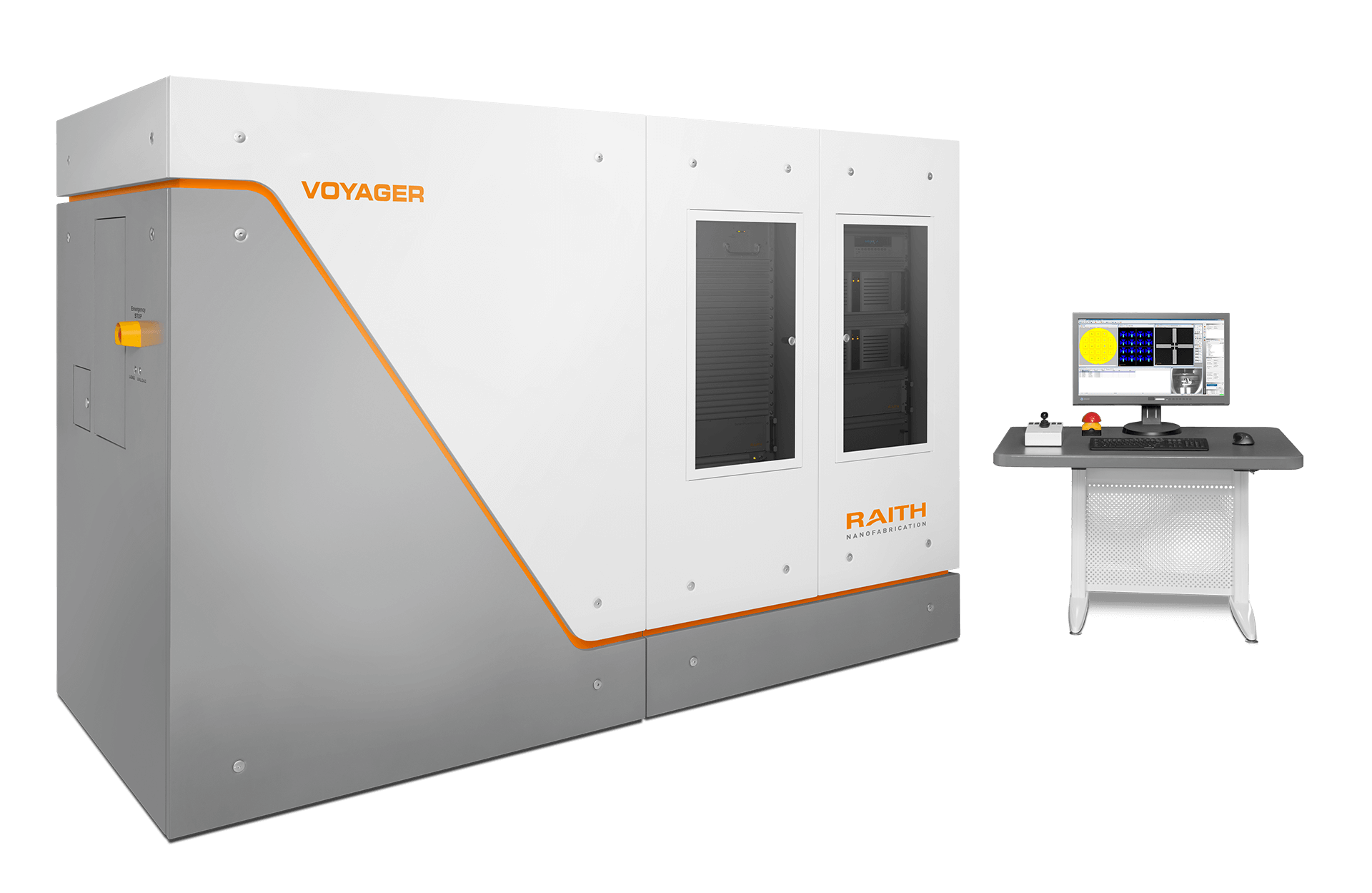

The George Washington University (GW) recently received multiple instruments from the Raith product portfolio to serve its interdisciplinary nanoscale research community at the new Science & Engineering Hall, and important results have already been achieved. Raith’s VOYAGER system will be the high performance Electron Beam Lithography system in the class 100 cleanroom at the Nanofabrication and Imaging Center, servicing applications in photonics, electron optics, materials, and life sciences.

With a unique CHIPSCANNER option and laser interferometer stage, the PIONEER system will serve as an SEM and EBL educational tool in the Micro / Nano Teaching Lab. Additionally, the PIONEER will capture large-area, high-resolution SEM images for neuroscience with unique and unmatched accuracy.

“Our multi-instrument project with The George Washington University illustrates how Raith’s expanded product portfolio of ultra-accurate instruments can serve myriad needs of a diverse community engaged in nanoscale science and engineering. Backed by its talented, local support personnel, the GW community is already using Raith’s instruments for generating unique results in neuroscience and educating the next generation of engineers.” – Dr. Jason E. Sanabia, President & CEO, Raith America.

“Our new Nano-fabrication and Imaging Center (NIC) is advancing our research and education mission, and Raith instruments are playing a pivotal role. The Raith PIONEER was critical for us to run a nanotechnology course over the summer sponsored by the NSF Nanotechnology Undergraduate Education (NUE) in Engineering program and we have plans to incorporate the instrument into other courses in our curricula. Being our first nanofabrication clean room, Raith’s support, flexibility, and rapid progress on installations has certainly been instrumental for GW. ” – Professor Can E. Korman, Associate Dean of Research and Graduate Studies, School of Engineering & Applied Science, GW.

“My favorite piece of equipment in the cleanroom would have to be the Raith EBL [PIONEER]. The flexibility of the device is mind blowing and amazes me that it can both be an SEM and a lithographer. The two functions can unite both characterization and fabrication.” – NSF NUE Student Fellow.

“In considering my experience working with the array of tools presented to us this summer, I would say my favorite has been the EBL. I find the EBL to be the most powerful tool we have used. The EBL is interesting to me because we can both image and pattern nano-scale devices.” – NSF NUE Student Fellow.

“The collaboration between GW NIC and Raith has rapidly resulted in the most accurate large-area, high-resolution map of neuronal tissue directly acquired by an SEM instrument. This innovative and transformative approach was a result of a unique intersection between the high-end Raith technology and intellectual merger between engineers and neuroscientists. As a result the reverse engineering approach to imaging neuronal tissue employs a unique combination of high resolution scanning electron microscopy, laser interferometer stage positioning, and field of view mapping to produce very large area (2×2 mm), stackable SEM image mosaics sets with very high accuracies and resolution (10 nm pixel). This approach minimizes the need for further image processing for error removal, which until now has been a limiting factor in neuroscience and particularly in connectomics.” – Anastas Popratiloff, Lead Research Scientist with the Office of the VP for Research and Professor of Anatomy and Regenerative Biology, The George Washington University

“Raith’s extensive experience in EBL and SEM instrumentation has culminated into the CHIPSCANNER, which for years has been the standard for IC reverse engineering in the semiconductor industry. Accurate, highest resolution SEM image mosaics have always played an essential role in reverse engineering and have proved its accuracy already for 22nm node technology. Raith’s long-term experience in reverse engineering helps a lot for this ‘new’ application of large area imaging for neuronal tissues.” – Martin Rasche, Senior Product Manager, Raith GmbH