FIB-SEM for FIB-centric nanofabrication

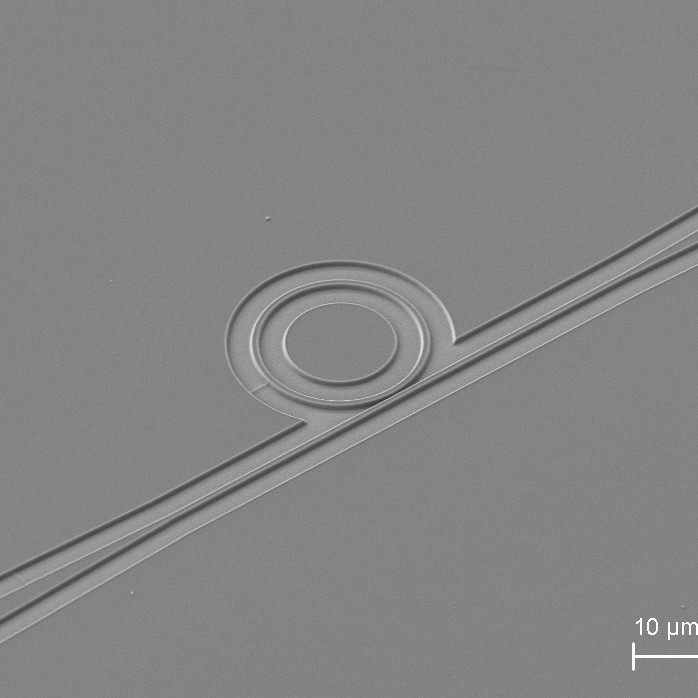

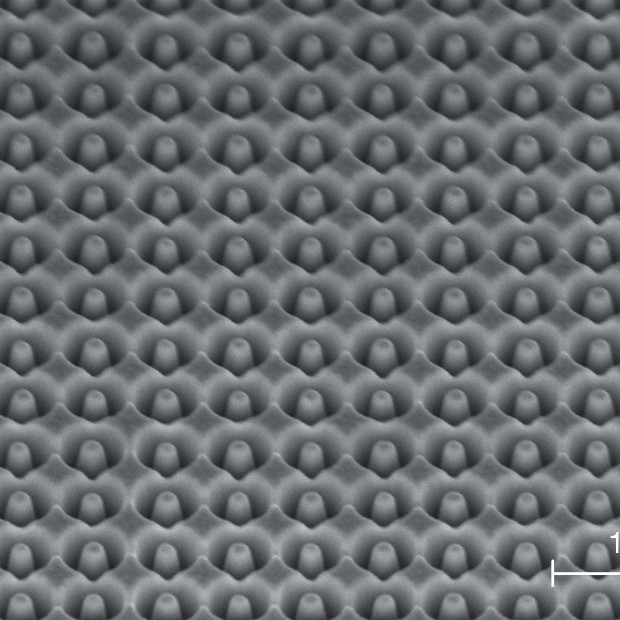

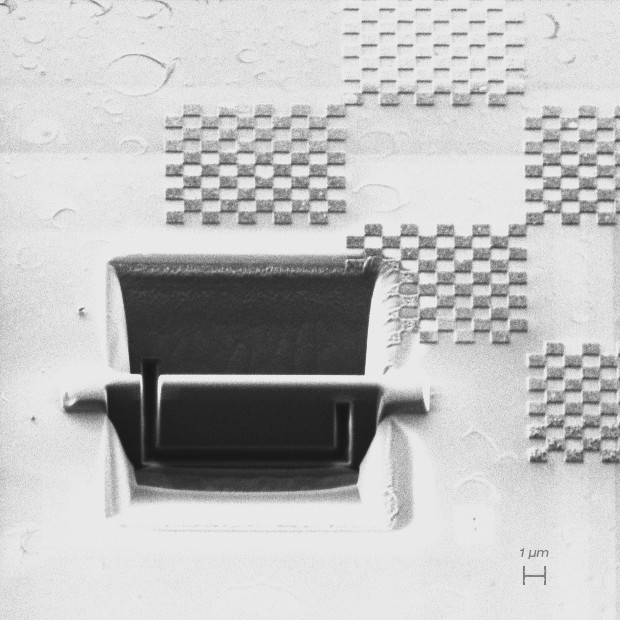

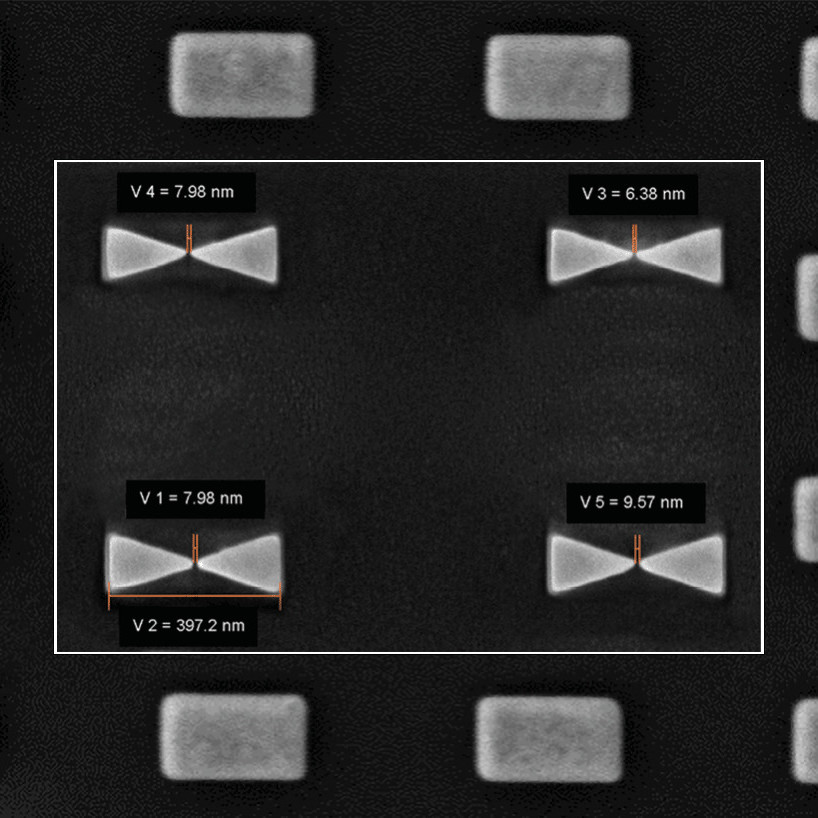

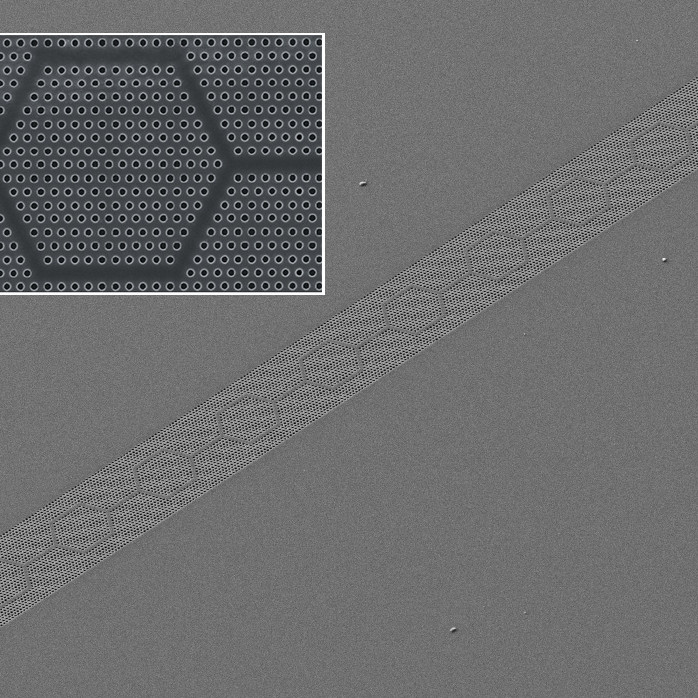

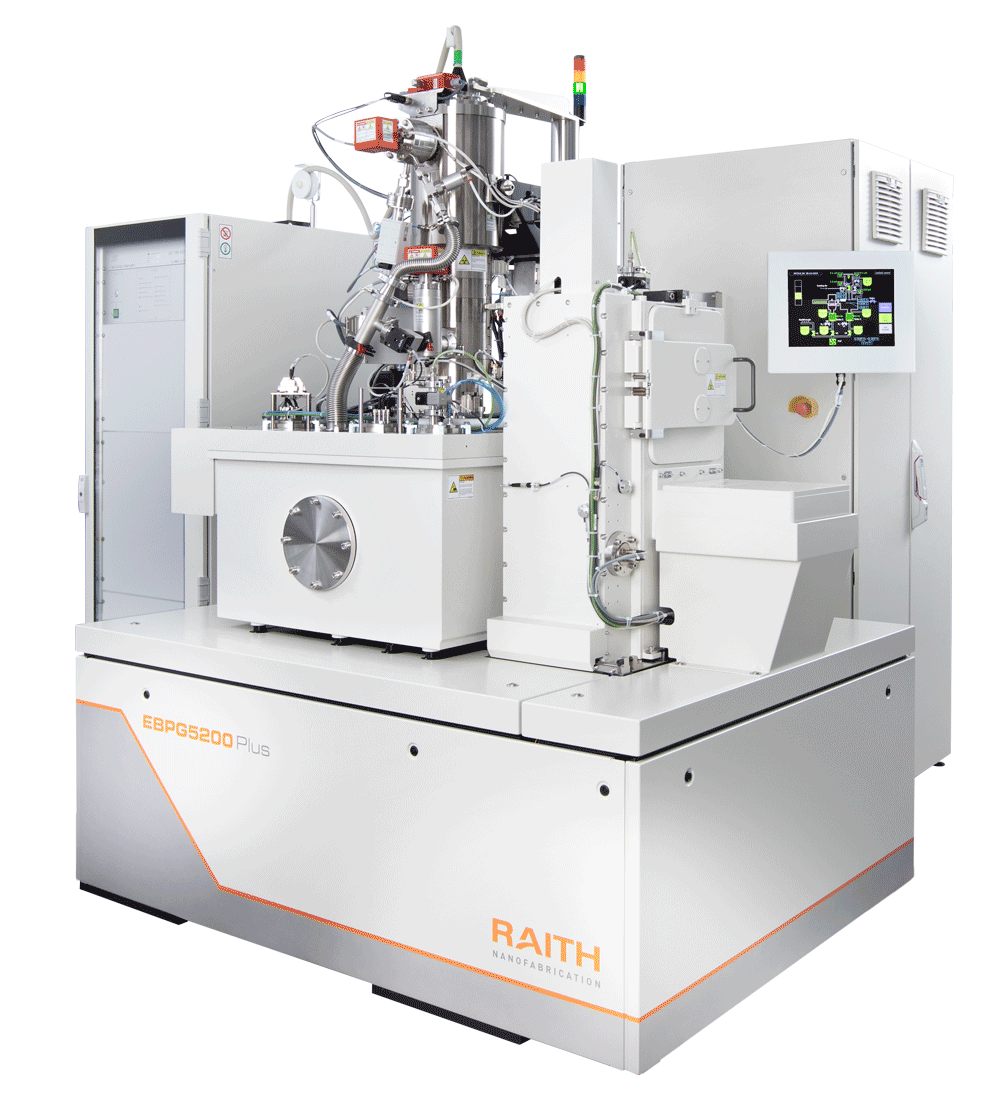

VELION is a novel FIB-SEM instrument concept for nanoscale science and engineering. FIB nanofabrication is established as a standard technique for fabricating three-dimensional and high-resolution nanostructures such as plasmonic devices, nano-fluidics, localized implantation, and functionalization. VELION meets the demanding requirements of nanofabrication. The concept comprises a configurable platform with features including:

- Dedicated nanoFIB ion column

- Liquid metal alloy source for multi-species ion beam technology

- Laser Interferometer Stage

- Tailored FE-SEM column

- Various options / system configurations including gas injection and nanomanipulators

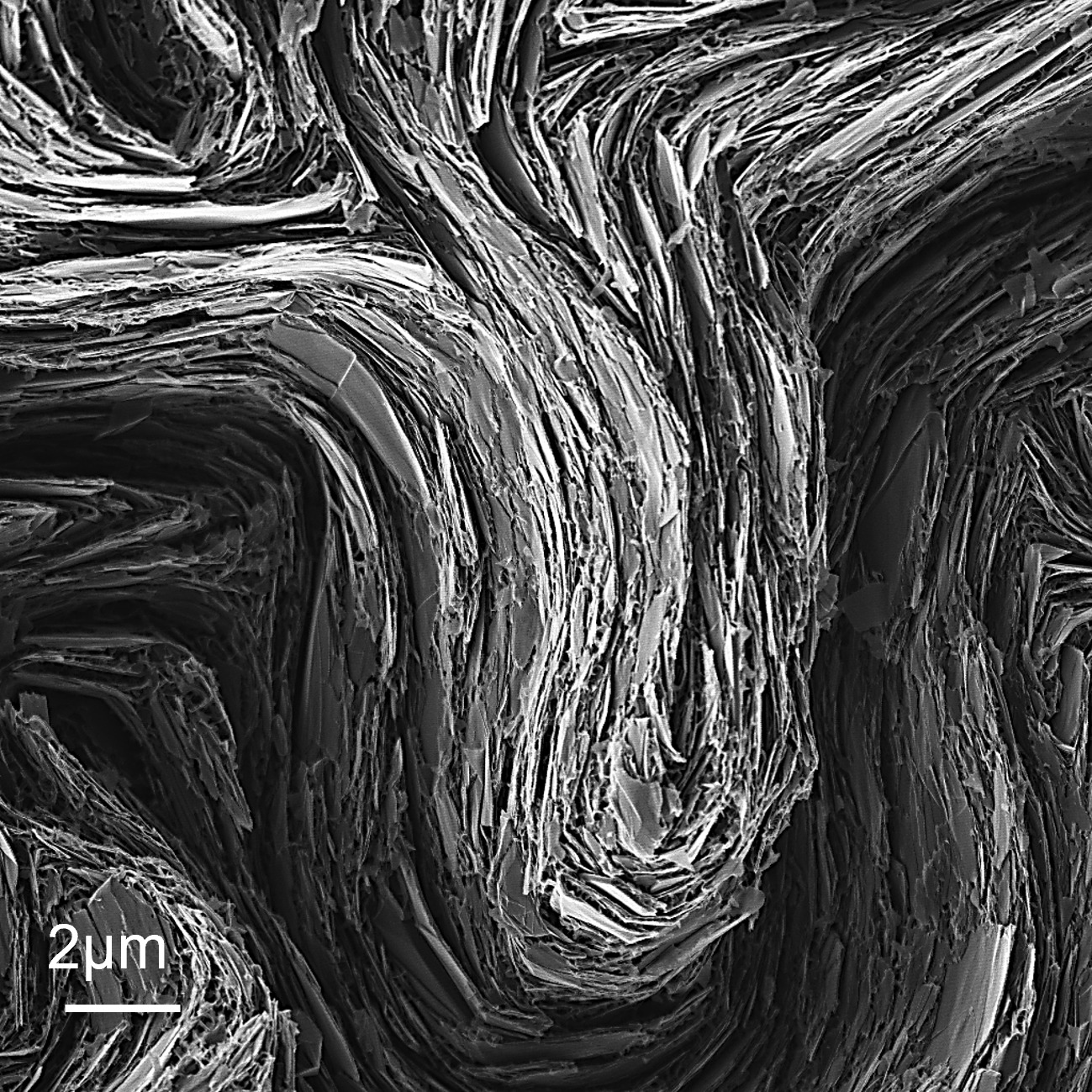

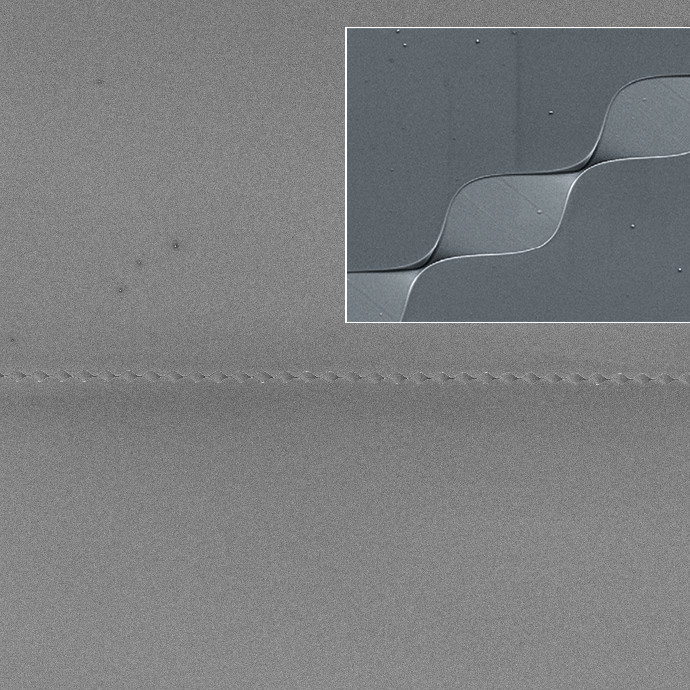

VELION features a vertically mounted FIB-column and side-mounted SEM. In combination with Raith’s Laser Interferometer Stage and mature lithography technology, VELION represents a unique FIB-SEM nanofabrication set-up. The dedicated FIB-centric system architecture ensures unrivaled stability, accuracy, and automation. Even the most complex structures in both 2D and 3D can be fabricated completely unattended to the highest precision standards over extensive areas and long periods.

Moreover, IONselect technology offers a range of ion species to choose from. This feature will pave the way for new breakthroughs in next-generation research. Adaption of ion properties to specific application enhances FIB processing. Find out more about the nanoFIB column here.

To get more in-depth information about either the nanoFIB column or the IONselect technology, you can also download the according White Papers.

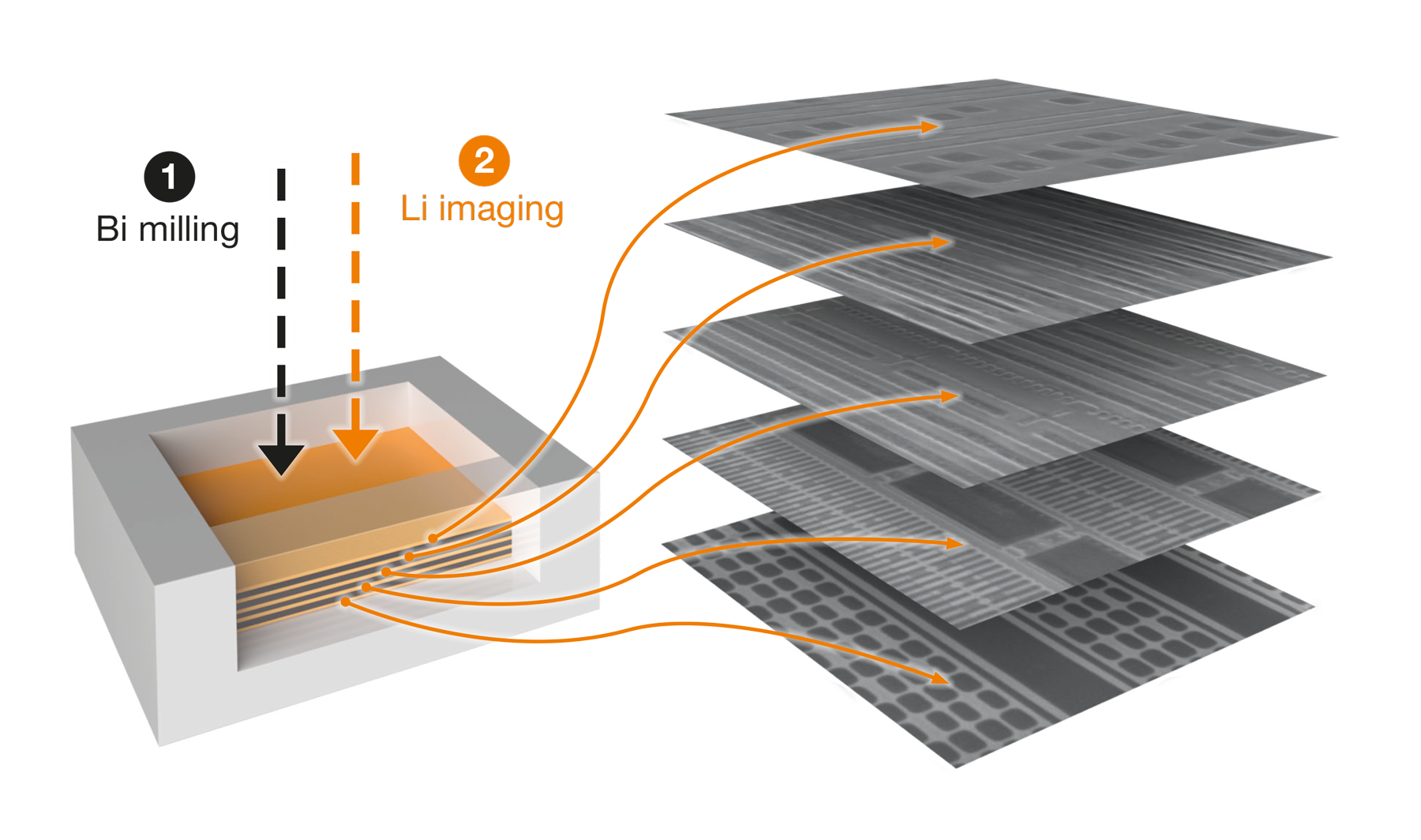

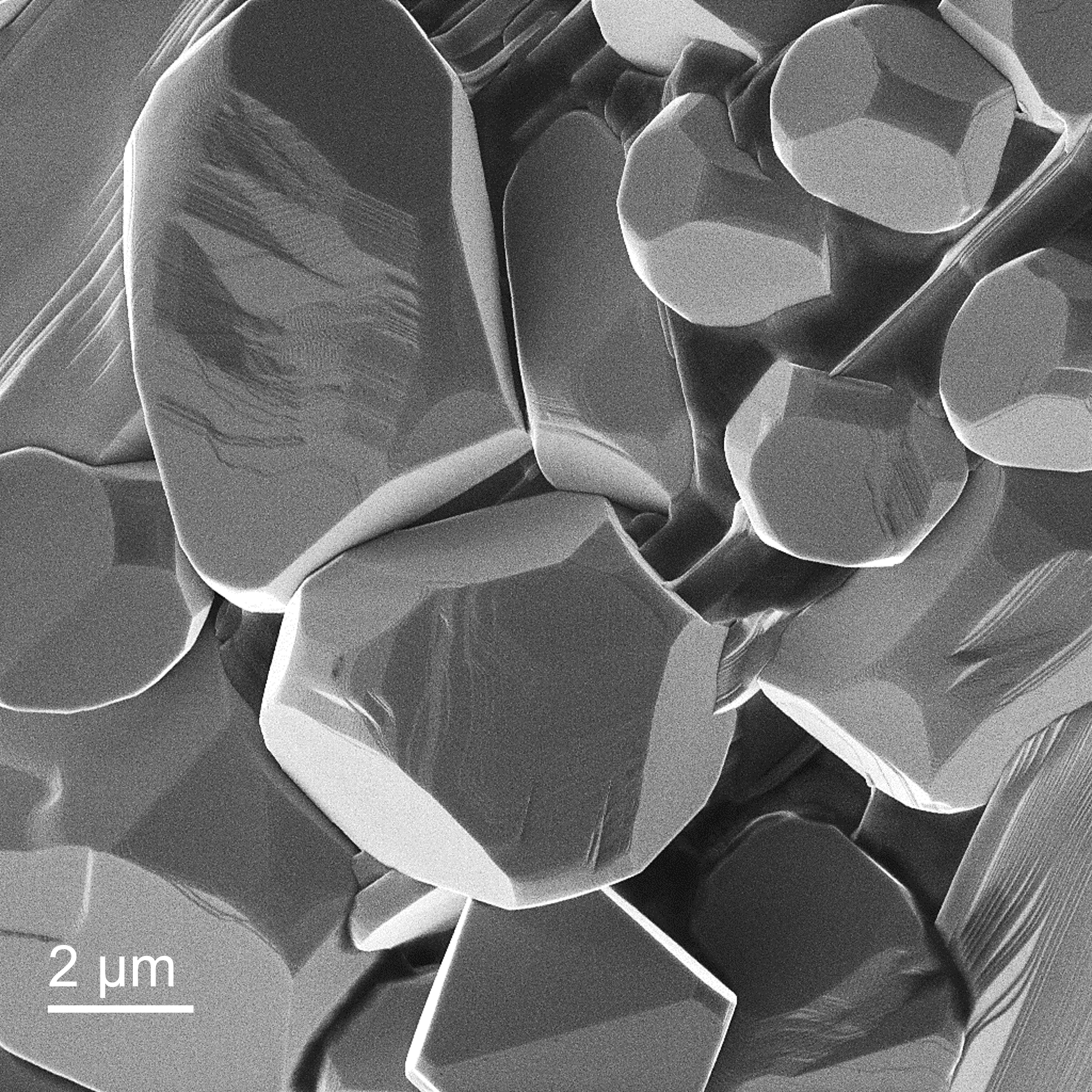

High-resolution ion microscopy with 3D reconstruction capabilities

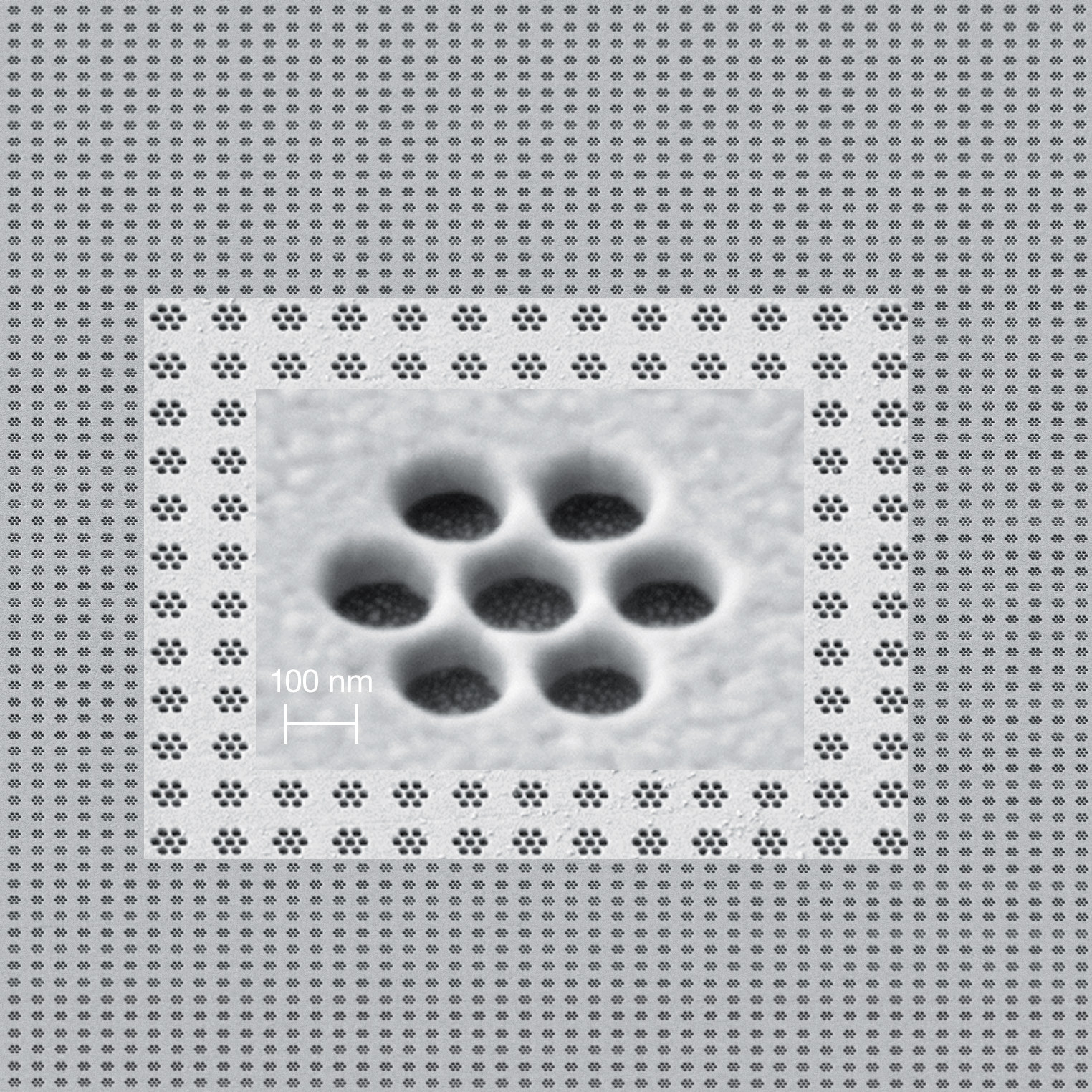

The modern FIB column design for innovative nanofabrication also provides the perfect setup for high-resolution FIB imaging. The proprietary multi-species ion source technology enables gallium, bismuth, and lithium ions emitted from the same source to be employed, using a subsequent Wien filter to minimize switching time. As the lightest ion available for LMAIS, lithium enables highest lateral resolution ion images, while the heavy Ga ions and Bi ions or Bi clusters can be used for precise vertical milling. Combining these capabilities in one tool together with the precision of the laser interferometer stage, VELION becomes a powerful ion microscope for 3D imaging.

Features

A single source providing

multiple ion species

Feature size:

sub 10 nm

Configurable FIB-SEM on a

lithography platform

Configurable setups for enhanced versatility

Offering numerous universal ports, VELION represents a configurable platform.

An array of optical cameras, gas injection systems, and Cartesian nanomanipulators are essential components for FIB-SEM systems and can be set up as required by the applications. The system layout is individually configurable and future upgrades can easily be implemented.

Further options include e.g. sample auto height sensing, customized sample holders, plasma cleaner, and many more.

Applications

Service

Specifications and system performance parameters are certainly drivers of decision-making where VELION is concerned. However, more factors need to be taken into consideration if efficient operation, continous uptime, and subsequent reliable support are to be ensured over the instrument system’s lifetime.

With a worldwide team of professional service engineers, Raith Service ensures you can make the best use of your system. When you decide on a Raith system, all site surveys together with environmental measurements, support with the resulting cleanroom laboratory setup, factory and on-site acceptances, and comprehensive on-site training are always included. Moreover, application support is available free of charge in all global time zones.

Raith service contracts follow a modular scheme and can be configured to match your individual requirements and budget. Visit our Service site or get in touch with us to learn more.

Download VELION brochure

To find out more about the VELION, the possible applications and specifications download the VELION product brochure