Key features

Easy switching between multiple ions from a single source within a few seconds while maintaining a stable ion beam

Tailored nanostructures

Enhanced ion

imaging

Vast number of application fields

Optimized sample patterning

Application-specific primary ion beams for SIMS

A new benchmark for nanoengineering applications

Source

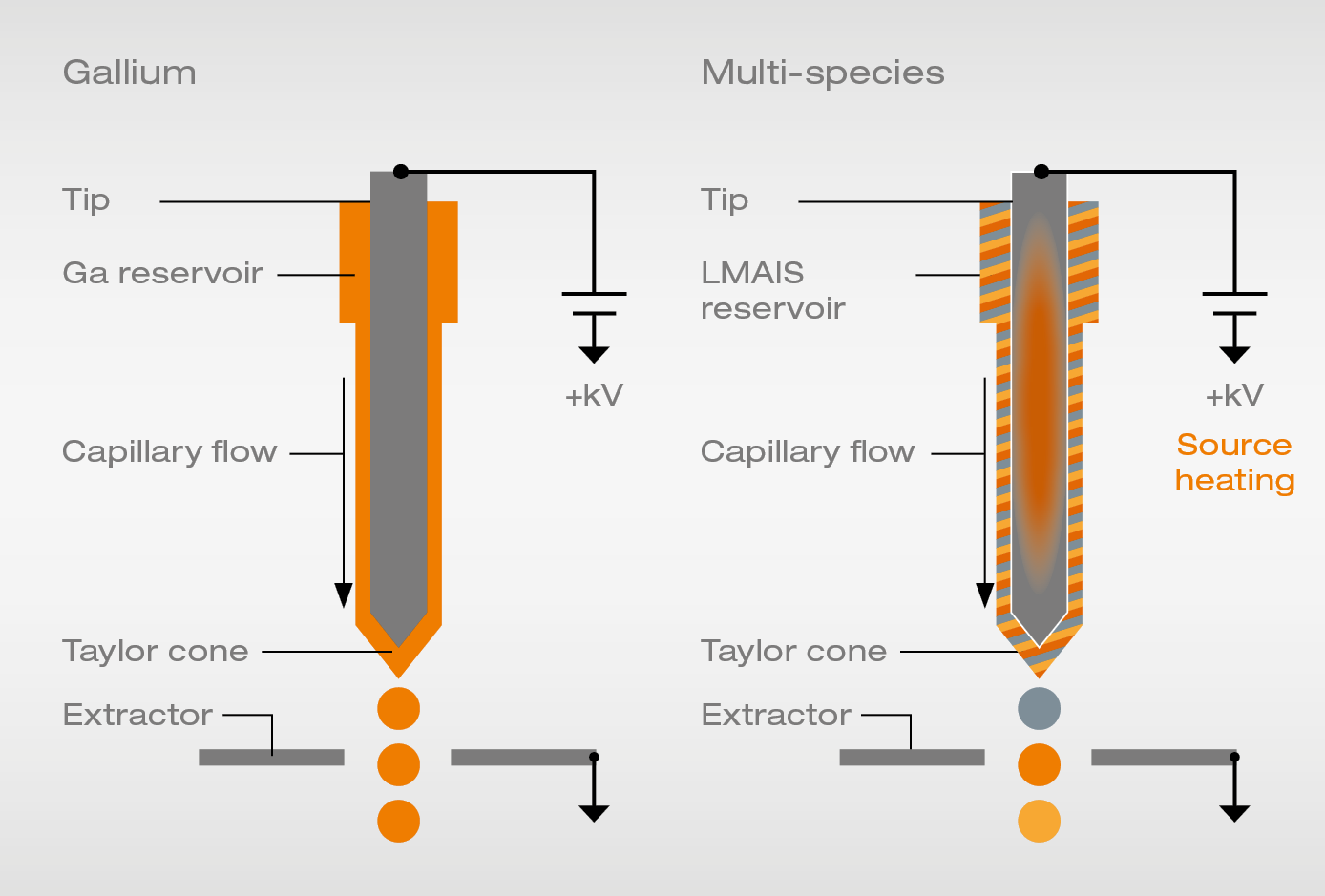

Unlike Gallium, eutectic alloys used in LMAIS are solid at room temperature and require heating for operation. Typically, eutectics need only a few hundred degrees Celsius for liquefaction, significantly lower than the melting point of the alloy’s pure components. This makes LMAIS ideal for producing various ions with moderate source heating.

Both Ga sources and LMAIS share a common mechanical setup and working principle: a reservoir containing Ga or eutectic alloy is connected to a metallic needle. Ion emission is initiated by applying an extractor voltage to create a strong electric field near the tip.

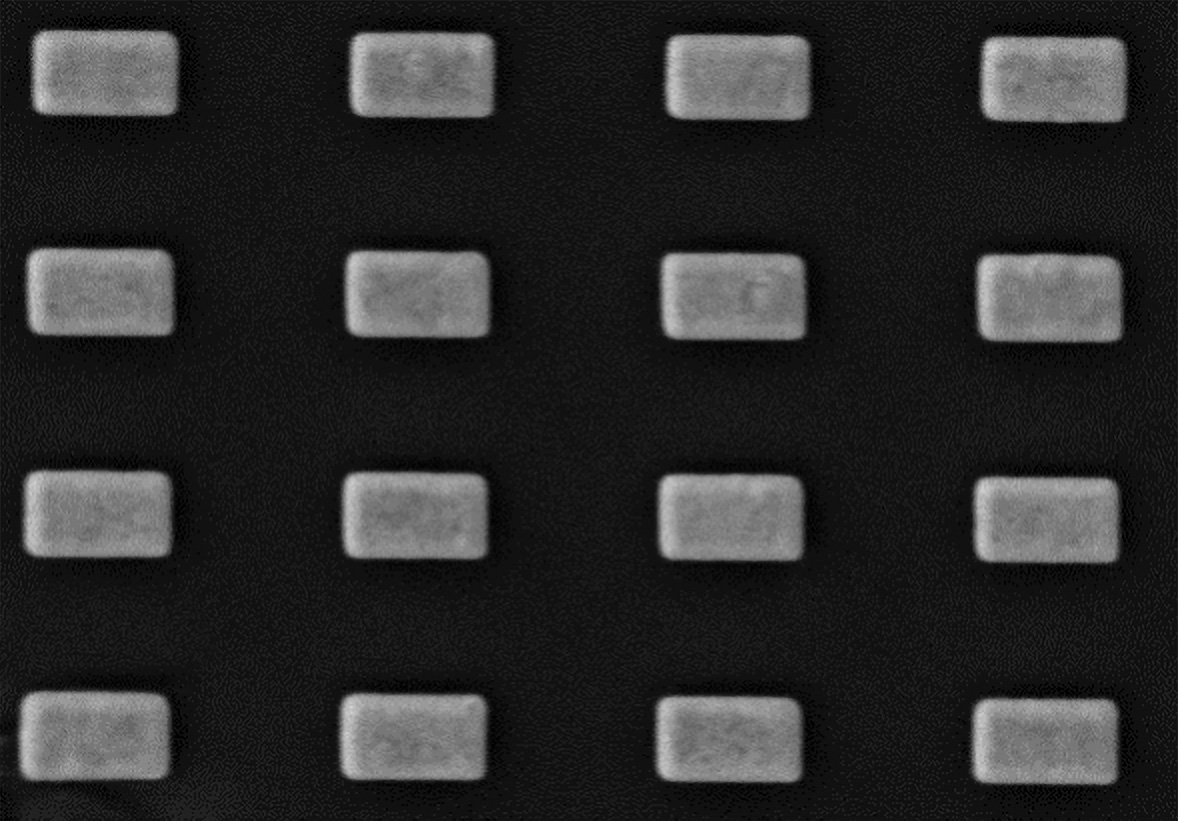

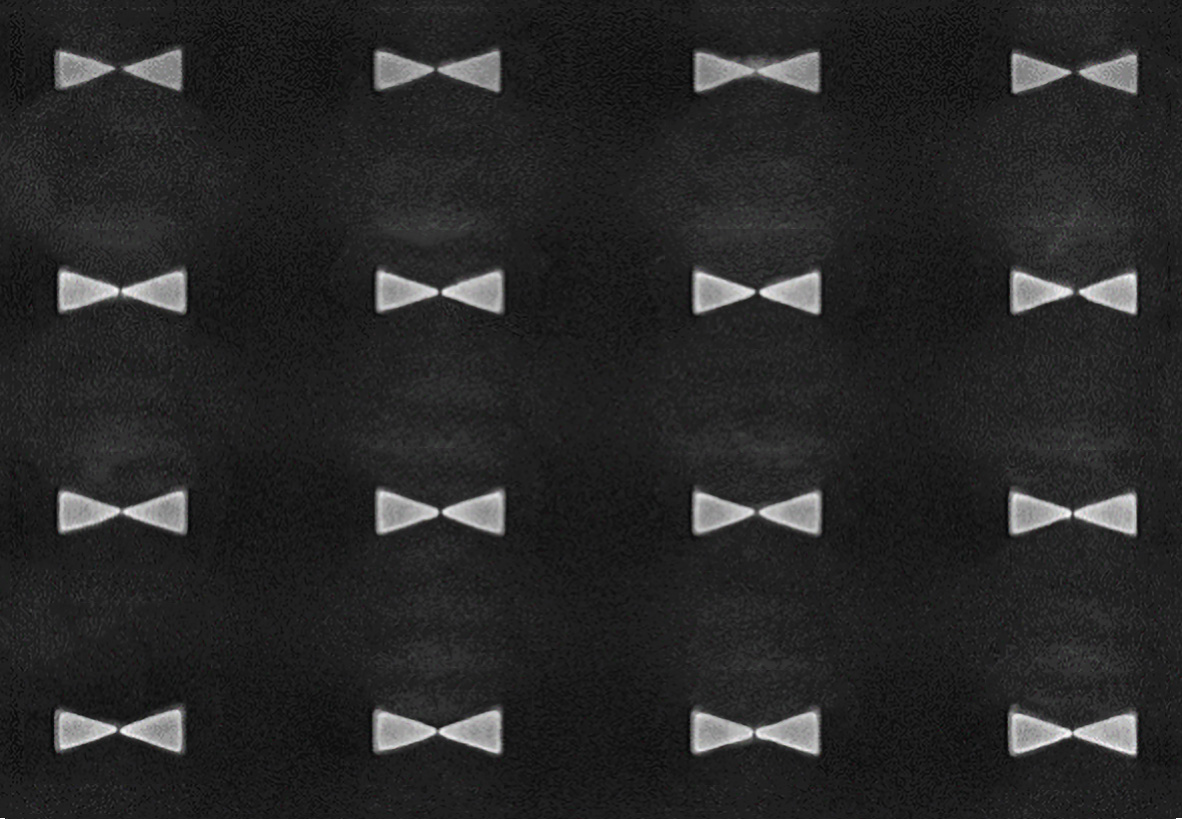

Left: Ion image of chessy sample generated by Bismuth focused ion beams. Ions are quickly changed from Bismuth to Lithium.

Right: Ion image of the same sample area generated by Lithium ions without offset and without beam settling time.

Wienfilter

Since the liquid metal alloy ion source emits various ions or clusters of different charge states simultaneously, switching between multiple ion species (m/q) is necessary. This is easily achieved by utilizing an ExB filter system, maintaining high resolution nanoFIB performance. A permanent magnet, located outside the vacuum column, provides a constant B field to eliminate hysteresis effects.

Adjusting voltages changes the required electrical field, facilitating separation of different (m/q) ions. Quick, reliable toggling between different ion species, clusters, or charge states is possible without mechanical realignment, as only the electrical field of the ExB filter needs adjustment for ion switching.

Use case

A good example of using both light and heavy ions from a single source in nanofabrication is the fabrication of bow ties. In the first step, heavy bismuth ions are used to remove a large volume of material and retain only small rectangles. In the second step, light lithium ions are used to refine the structure and carve out the bow ties. The entire process can be run automatically, with quick and reliable switching between ion species. This approach leverages the high sputter yield of bismuth and the high resolution of lithium, resulting in a faster and more accurate fabrication process.

resolution