Key features

Applicable with two different writing modes (FBMS / MBMS) in our electron beam lithography and FIB systems

Writing of large photonic devices as optical waveguides

uniformity.

Ideal for periodic patterns fabrication

Fully integrated into Nanosuite software

Efficiency

Precision in motion: Achieving (sub) nanometer writing accuracy

Successful writing with continuously moving stage down to (sub) nanometer precision requires very accurate and smooth mechanical motion, extremely fast path calculations, as well as instant corrections of any following error. Therefore, a laser stage based on RAITH’s UltraPositioning technology is combined with a very fast motion controller specifically developed for this purpose. The motion controller calculates a two-dimensional, continuous trajectory with stable velocity and drives the stage in closed-loop control based on interferometer feedback.

Highly accurate linear bearings and a special drive chain ensure very smooth and continuous movement of the laser stage and the sample. Disturbances and deviations that cannot be mechanically corrected in time due to the inertia of the stage are instantly compensated by beam deflection, called beam tracking. This is realized by a direct interface between the motion controller and pattern generator, which is also used for patterning synchronization.

Advanced beam tracking for enhanced patterning control

Beam Tracking continuously superposes further beam deflections depending on the dedicated exposure mode.

FBMS: Fixed Beam and Moving Stage

In FBMS mode, the width of the path is defined by dynamic beam expansion. The beam remains virtually stationary while the stage underneath follows arbitrary shaped paths of the desired patterns.

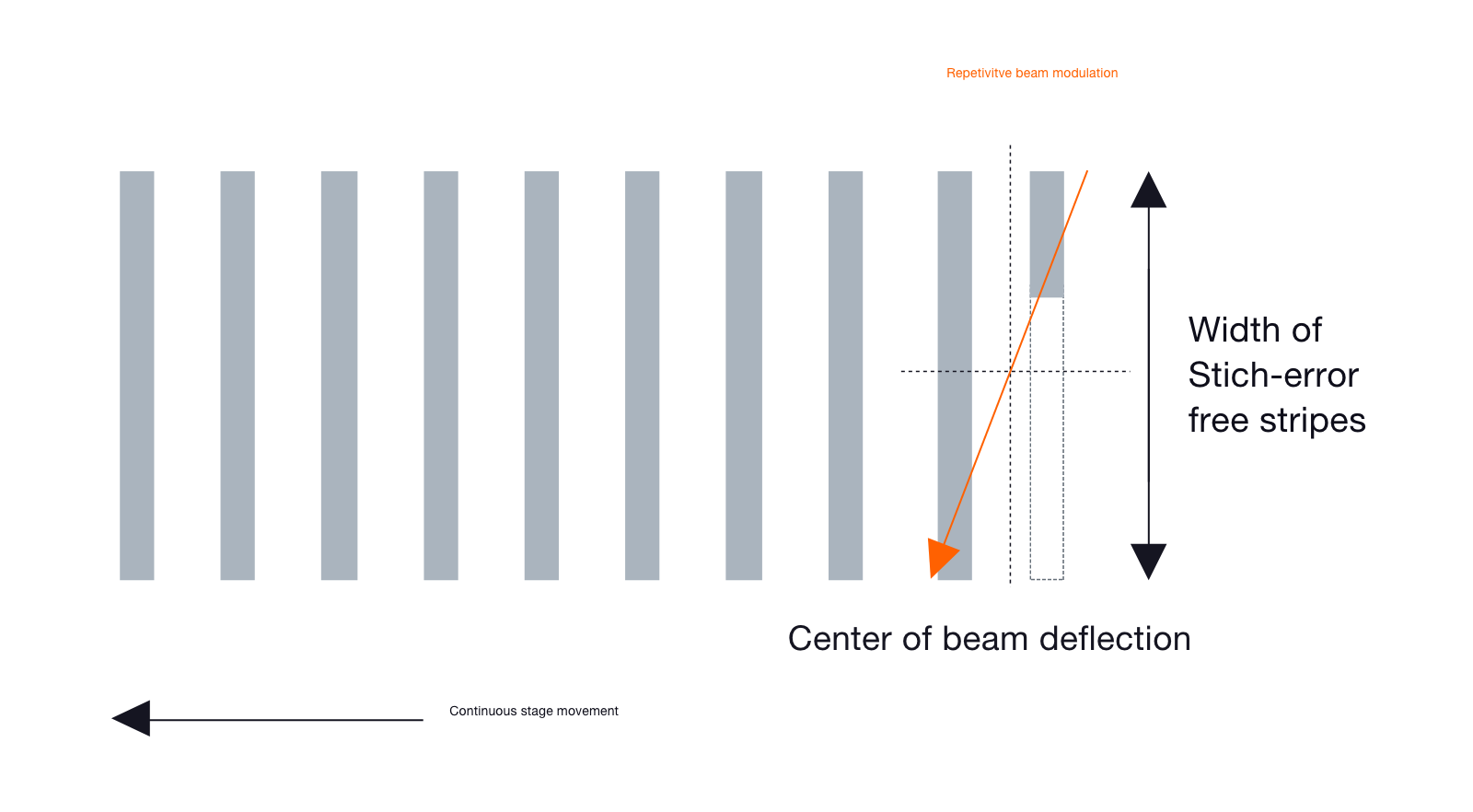

MBMS: Modulated Beam and Moving Stage

For MBMS exposures, the stage is driving straight paths and a feedforward correction is applied to the pattering. The (repetitive periodic) beam movement is defined such that the combination of patterning and synchronized continuous movement of the laser interferometer stage results in the designed periodic structures. The MBMS implementation allows excellent pitch control by means of stage velocity control in combination with beam deflection.