Introduction

The transfer of innovation from Lab-to-Fab requires Fab-compatible processes and protocols in Labs. VECTOR combines key capabilities such as process characterization, lithography process control, defect review, and inspection in one automated SEM. Precise and automated measurements are crucial in transferring cutting-edge nanotechnology into new industry devices. VECTOR bridges the gap between manual analytical SEMs and dedicated costly CD-SEMs production systems, making it the most suitable solution for academia, core facilities, and industry.

Benefits

Taking SEM measurements to the next level

Automated workflows without user influence

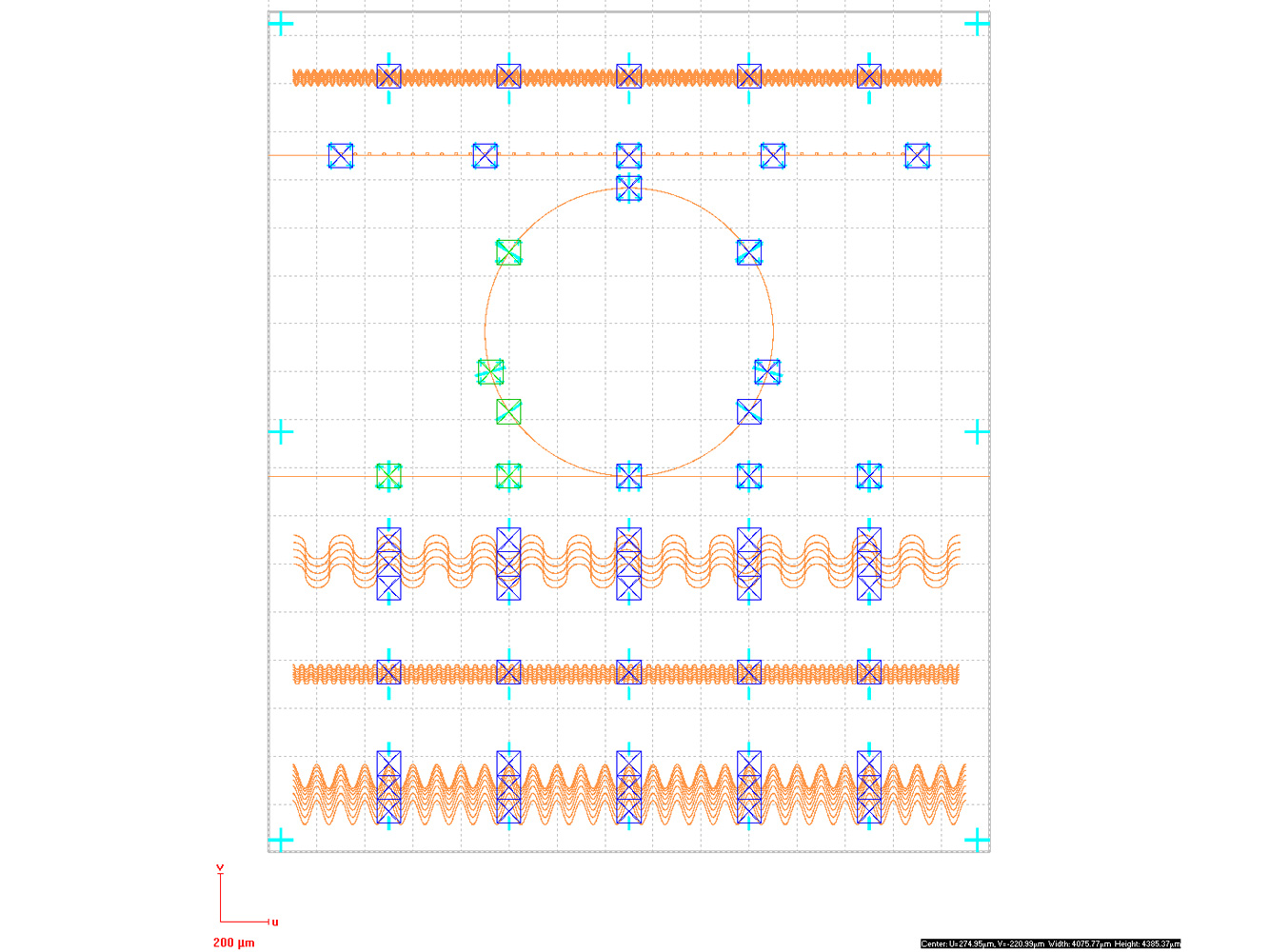

With CAD-file and / or KLARF import, VECTOR has ultimate navigation and automation capabilities. Recipe based job files for automated acquisition and evaluation of 10.000s of images can be easily generated.

Precision guaranteed

High-resolution sensors and automated calibration routines guarantee the mandatory precision and accuracy for full-wafer inspections.

Enhanced positioning accuracy

The integrated laser interferometer stage achieves 1 nm positioning accuracy across the wafer – no more image counting. Plus, the environmental shield eliminates external influences like vibrations, temperature drifts, and magnetic fields.

Connectivity

VECTOR can be connected to all RAITH nanofabrication systems to fuel yield and productivity improvements, as well as enhance ease of use. Innovation cycle times will be reduced.

Fast

Scan

Ultra

Positioning

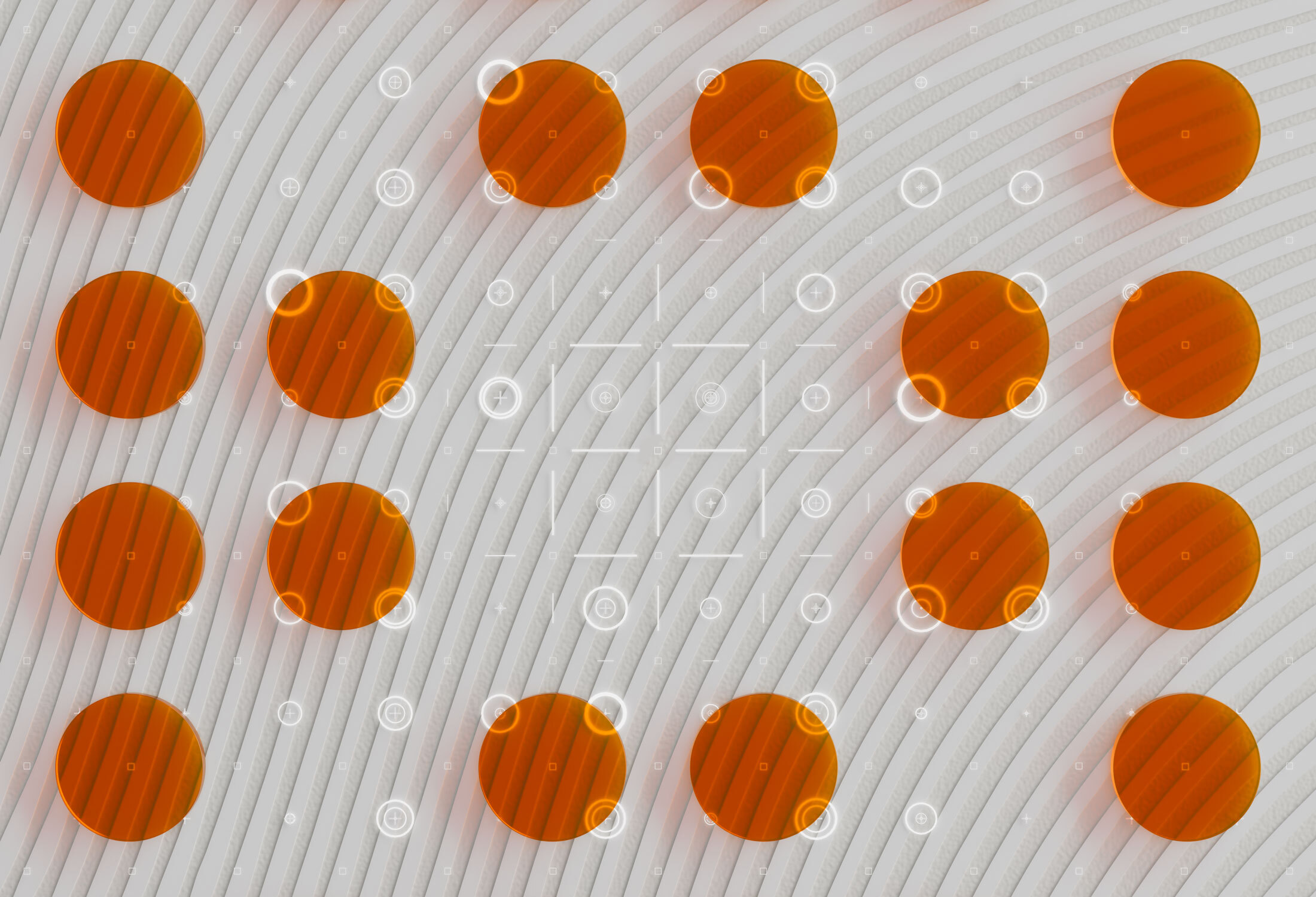

3-in-1 solution for characterization and verification of nanostructuring processes

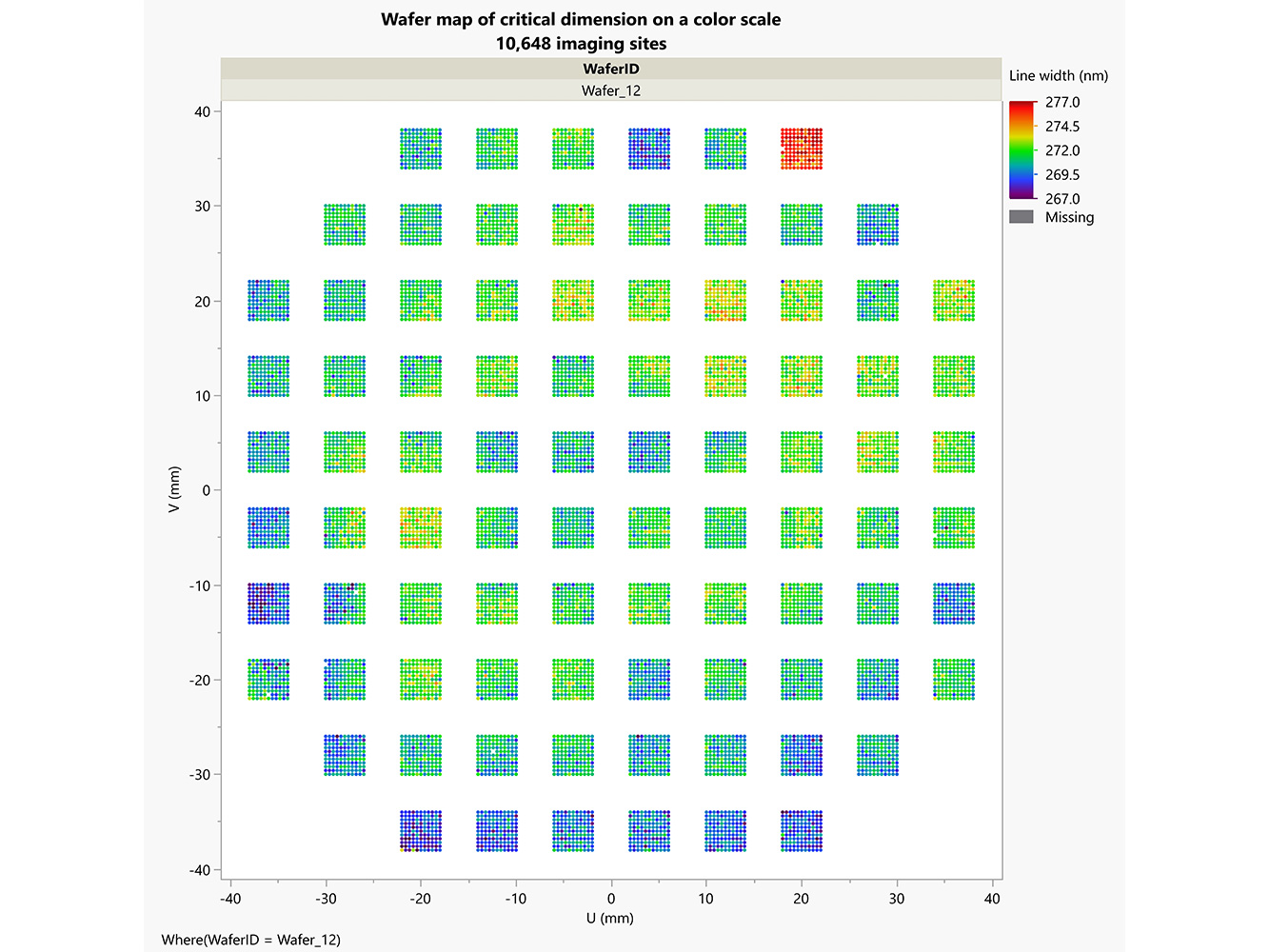

Automatically evaluate metrology parameters such as CD variation, gap size, LER, etc., facilitating efficient process window analysis and control

Automated SEM imaging

Metrology

Defect inspection

Software

Creating information out of data

Design and execute complex patterns

The proprietary Digital RAITH Nanosuite control software, with its various modules, is the most comprehensive platform for integrated solutions and additional external software modules.

Configurable analysis capabilities

- Metrology

- Defect review

- SEM-inspection

- Defect review

- SEM-inspection

Python scripting

Interface with Python scripting for extended automation and customizing.

Connectivity

Direct import of inspection poins/areas of interest from RAITH nanofabrication tools like electron, laser, or ion beam writers.

100 person-years of software programming

Technical data

Comprehensive database

Graphical display of results

Tunable and automated

column calibration procedures

Graphical display of results

Tunable and automated

column calibration procedures

Dedicated software

Measurement precision

1 nm 3 sigma

Measurement accuracy

Within +/- 0.02%

of NIST traceable

standard

of NIST traceable

standard

Beam position stability

≤ 200 nm / 8 hrs

High accuracy over the full travel range also enables precise long-distance measurements much larger than one field of view (FOV)

≤ 0.5 % / 8 hrs

Image resolution

< 1 nm

Are you interested in more details and insights?

VECTOR brochure (.pdf)

Application use cases

Bringing applications to perfection

Solutions

RAITH offers integrated solutions that increase performance and create market opportunities. In any production environment.

Process Control

Revolutionize nanofabrication quality management, enable extensive data acquisition at the nanoscale, and beyond.

Mix and Match

Seamless blending of laser direct writing, ion beam, and electron beam technologies, unlocking new nanostructuring horizons.