Gratings with sub- 0.1 nm pitch fidelity

Today’s applications, such as video on demand and cloud services, demand the utmost of bandwidth requirements for mobile networks and landline-based internet access points. Only modern fiber optic communication networks can deliver the bandwidth required for backbone structures or access points. The data transmission modules required for fiber optical communication include modulated diode laser sources such as distributed feedback (DFB) lasers as key devices. Where fabrication of the feedback structure of DFB lasers is concerned, electron beam lithography (EBL) has been regarded as an alternative manufacturing method in optical lithography from the outset. The approach offers a straightforward way of realizing complex diode structures containing single or multiple phase shifts, continuously varying line width, or chirped gratings.

The emission frequency of a DFB laser must be precisely defined according to its later use (type of network). This requires the DFB grating to have overall pitch fidelity in the range of 0.1 nm or lower, while at the same time the throughput of the EBL process must be as high as possible.

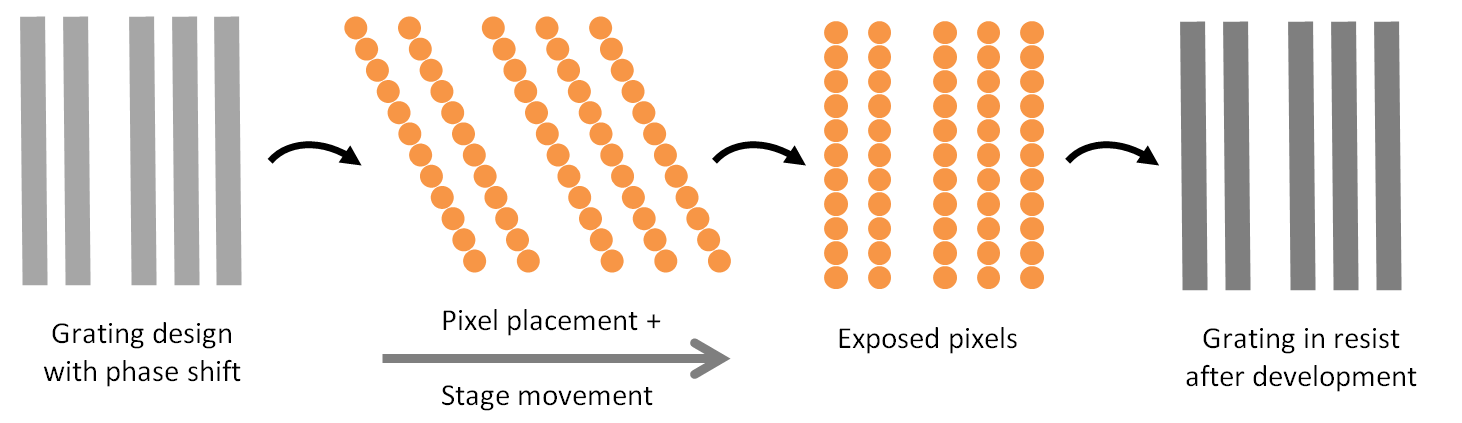

One promising approach to fulfill the demands described is RAITH’s MBMS (Modulated Beam Moving Stage) technology. During the patterning process of the substrate, the supporting stage is moved continuously along a predefined path. This method maximizes throughput by minimizing the overhead time of the patterning process. At the same time, the level of pitch control accuracy is increased significantly to the range of < 0.1 nm. Even complex structures such as phase shift gratings can be fabricated in this way. The patterning strategy is illustrated in the diagram in Figure 1.

Maximum accuracy in verification of the achieved pitch fidelity can only be reached using optical measurements, i.e. the emission wavelength measurement of the built laser. However, to obtain a fast pitch fidelity result, the grating structures can easily be evaluated using extended SEM metrology. A precise laser interferometer stage can determine the position of e.g. every 100th line with fidelity of approx. 1 nm. By dividing the measured distance by the number of periods, measurement resolution is increased to the range of e.g. 0.01 nm. An example of this approach is shown in Figure 2: the histogram shows the metrology of a grating with 300.03-nm target period. (The metrology resolution for evaluation of an SEM image is in the range of only 1 nm.) The maximum deviation measured from target pitch is less than 10 pm.

The given examples highlight RAITH’s MBMS writing mode delivering the required grating pitch fidelity for modern diode lasers. In addition to the high patterning accuracy the writing time in MBMS mode is reduced significantly with respect to the classical way using a fixed stage (wafer) position during beam-on time. Moreover the MBMS mode is very easy to use for the machine operator.